Why Use Shear Beam Load Cells for Livestock Scales?

TIME: 2026.01.23

AUTHOR: Carol Li

NUMBER OF VIEWS 144

If you’re in the livestock industry—whether you run a small family farm, manage a commercial feedlot, or operate a veterinary clinic—accurate animal weighing is non-negotiable. Livestock scales aren’t just tools for tracking growth; they’re critical for optimizing feed rations, ensuring compliance with transport weight limits, monitoring animal health, and maximizing profitability. But here’s the thing: even the best scale design falls flat if it’s paired with a subpar load cell.

Load cells are the unsung heroes of any weighing system, converting mechanical force (like the weight of a cow or pig) into an electrical signal that the scale’s display can read. With so many load cell types on the market—compression, tension, single-point—why are shear beam load cells emerging as the go-to choice for livestock scales? In this blog, we’ll break down the key benefits of shear beam load cells, address common challenges in livestock weighing, and explain why they’re a smart investment for any operation looking to boost accuracy, durability, and ROI.

What Are Shear Beam Load Cells, Anyway?

Before diving into their advantages, let’s start with the basics. A shear beam load cell is a type of strain gauge load cell designed to measure force by detecting the shear stress (sideways force) applied to a beam-shaped metal element. Unlike compression load cells, which absorb force directly along their axis, shear beam load cells are mounted horizontally, with the load applied perpendicular to the beam’s length.

Inside the load cell, a network of strain gauges is bonded to the beam. When an animal steps onto the scale, the beam bends slightly, causing the strain gauges to stretch or compress. This changes their electrical resistance, which the load cell’s circuitry converts into a precise weight reading.

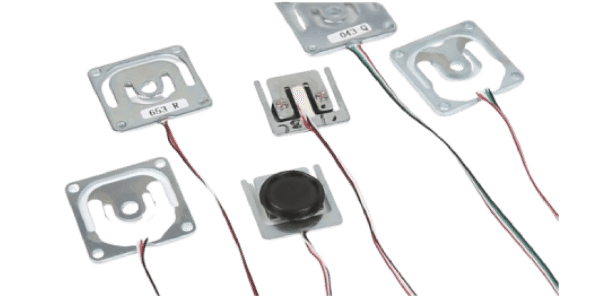

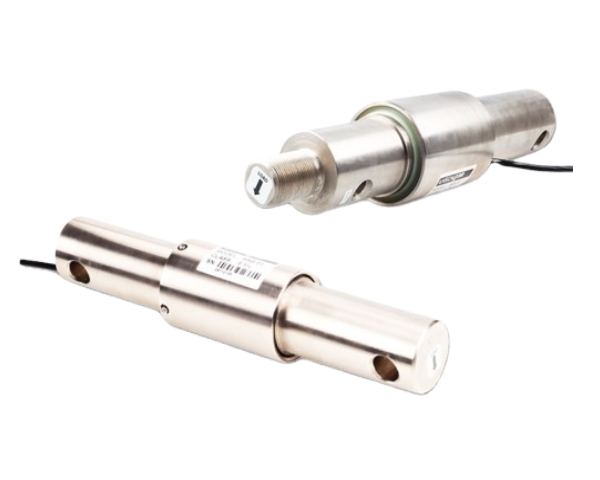

Shear beam load cells come in two main configurations: canister-style (for heavy loads, often used in large platform scales) and low-profile (slimmer, ideal for smaller scales or tight spaces). Both are built with robust materials like stainless steel or alloy steel, making them resistant to the harsh conditions common in livestock environments.

Key Challenges in Livestock Weighing (And How Shear Beam Load Cells Solve Them)

Livestock weighing isn’t like weighing a static box in a warehouse. Animals move, kick, and jostle; scales are exposed to mud, manure, and moisture; and operations need to weigh everything from tiny lambs to 2,000-pound bulls. Let’s look at the top challenges and how shear beam load cells rise to the occasion.

1. Unpredictable Loads: Overcoming Off-Center Weighing

Anyone who’s tried to weigh a wiggly goat or a stubborn cow knows: animals rarely stand perfectly centered on the scale. Off-center loading (also called “side loading”) is a major cause of inaccurate readings with many load cell types. For example, single-point load cells—common in small retail scales—are only accurate if the load is applied directly to their center. Tension load cells, used in hanging scales, can struggle with lateral forces from moving animals.

Shear beam load cells excel here because they’re inherently resistant to off-center loading. Their horizontal design and wide load-receiving area distribute force evenly across the beam, even if the animal stands near the edge of the platform. This means you get consistent, accurate readings whether the cow is leaning left, the pig is circling, or the sheep is huddled in a corner.

For commercial feedlots, this accuracy is a game-changer. A 2% error in weight for a 1,500-pound steer translates to a $30 loss at market (assuming $1.50 per pound). Over 100 steers, that’s $3,000 gone—all because of off-center loading. Shear beam load cells eliminate that waste.

2. Harsh Environments: Durability That Lasts

Livestock facilities are messy. Scales get splashed with water during cleaning, coated in manure, and exposed to extreme temperatures (from freezing winter barns to sweltering summer pastures). Many load cells fail prematurely in these conditions, but shear beam load cells are built to withstand them.

Most shear beam load cells are made with stainless steel, which is corrosion-resistant and easy to clean. They also feature sealed enclosures (rated IP67 or higher) that prevent dust, moisture, and debris from entering the internal components. IP67 protection means the load cell can be submerged in up to 1 meter of water for 30 minutes—perfect for hosing down the scale after weighing a group of pigs.

Compare this to compression load cells, which often have exposed components that are prone to rust. A farm in Iowa reported replacing their compression load cells every 2 years due to corrosion, but after switching to stainless steel shear beam load cells, they haven’t needed a replacement in 5 years. That’s a huge reduction in maintenance costs and downtime.

3. Heavy Loads: Handling Large Livestock Without Compromise

Cattle, horses, and bison can weigh well over 1,000 pounds, and even smaller animals like pigs and goats add up when weighed in groups. Shear beam load cells are designed for high capacity—some models can handle up to 50,000 pounds per cell. This makes them ideal for large platform scales used in feedlots, auction houses, and transport yards.

But high capacity doesn’t mean sacrificing accuracy. Shear beam load cells maintain their precision even at maximum load, which is critical for compliance with transport regulations. In the U.S., for example, commercial trucks carrying livestock must adhere to state and federal weight limits to avoid fines. A scale with shear beam load cells ensures you know exactly how much your trailer weighs, so you can avoid overloading and stay legal.

4. Vibration and Shock: Reducing Wear and Tear

Animals don’t step gently onto scales. A 1,200-pound cow jumping off a ramp can create a shock load that damages sensitive load cells. Shear beam load cells absorb these shocks better than other types because their beam design distributes force across a larger area. This reduces stress on the internal components, extending the load cell’s lifespan.

Vibration is another issue—especially in mobile scales used in pastures or auction yards. Shear beam load cells have a higher natural frequency than compression load cells, which means they’re less affected by vibration. This results in more stable readings, even when the scale is placed on uneven ground or near a running tractor.

Additional Benefits of Shear Beam Load Cells for Livestock Scales

Beyond solving the biggest challenges, shear beam load cells offer several other advantages that make them a top choice for livestock operations.

Easy Installation and Maintenance

Shear beam load cells are relatively easy to install, even for farmers with limited technical experience. They mount horizontally to the scale’s frame, and most come with pre-drilled holes for quick attachment. Unlike tension load cells, which require complex hanging systems, shear beam load cells can be installed in a matter of hours.

Maintenance is also simple. Because they’re sealed and corrosion-resistant, you don’t need to disassemble them for cleaning. A quick hose-down after each use is usually enough to keep them in good condition. And if a load cell does need to be replaced, most models are interchangeable with minimal calibration—saving you time and money.

Long-Term Cost Savings

While shear beam load cells may have a higher upfront cost than some other types, they pay for themselves over time. Their durability means fewer replacements, and their accuracy reduces waste from overfeeding or underweight sales. Let’s do the math:

Suppose a dairy farm with 50 cows switches from compression load cells (which need replacement every 2 years, $200 per cell) to shear beam load cells (replacement every 5 years, $300 per cell). Over 10 years:

-

Compression load cells: 5 replacements x 4 cells x $200 = $4,000

-

Shear beam load cells: 2 replacements x 4 cells x $300 = $2,400

That’s a $1,600 savings on replacements alone. Add in the savings from more accurate feed rations (reducing feed costs by 3%—$1,500 per year for a 50-cow farm) and the total savings jump to $16,600 over 10 years. That’s a significant return on investment.

Versatility Across Livestock Types

Shear beam load cells aren’t just for cattle. They work equally well for pigs, sheep, goats, horses, and even poultry. For example:

-

A small farm using a low-profile shear beam load cell in a lamb scale can get accurate readings down to 0.1 pounds, which is critical for tracking growth in young animals.

-

A poultry operation using a platform scale with shear beam load cells can weigh crates of chickens quickly and accurately, reducing stress on the birds and improving efficiency.

This versatility means you don’t need to buy different load cells for different animals—one system can handle all your weighing needs.

Real-World Success Stories: Farms That Switched to Shear Beam Load Cells

Don’t just take our word for it. Let’s look at two farms that saw dramatic improvements after switching to shear beam load cells.

Case Study 1: Maplewood Feedlot (Nebraska)

Maplewood Feedlot is a 5,000-head commercial feedlot that was struggling with inaccurate weight readings from their old compression load cell scale. Off-center loading from cattle was causing errors of up to 5%, which meant they were either overfeeding (wasting money) or selling underweight cattle (losing profit).

In 2020, they replaced their compression load cells with stainless steel shear beam load cells. The results were immediate:

-

Weight accuracy improved to within 0.5% of the actual weight.

-

Feed costs dropped by 4% (saving $28,000 per year) because they could adjust rations based on precise weight data.

-

They avoided two transport fines (totaling $1,200) because their scale readings were compliant with state weight limits.

“Switching to shear beam load cells was one of the best investments we’ve made,” said owner Mark Johnson. “The accuracy and durability have made a huge difference in our bottom line.”

Case Study 2: Willow Creek Farm (Vermont)

Willow Creek Farm is a small family farm that raises sheep and goats. They were using a single-point load cell scale that frequently gave inaccurate readings when animals stood off-center. This made it hard to track growth and adjust feed rations for their young lambs.

In 2021, they installed a low-profile shear beam load cell scale. The changes were noticeable:

-

They could now get accurate readings for lambs as small as 10 pounds.

-

The scale was easier to clean (thanks to the sealed load cells), which reduced the risk of disease spread.

-

They saved $1,200 per year on feed by avoiding overfeeding their sheep.

“The shear beam scale has made our daily tasks so much easier,” said farmer Sarah Miller. “We no longer have to fight to get the lambs to stand perfectly still—we just weigh them and go.”

How to Choose the Right Shear Beam Load Cell for Your Livestock Scale

Now that you know the benefits, how do you pick the right shear beam load cell for your operation? Here are a few key factors to consider:

1. Capacity

Calculate the maximum weight you’ll need to weigh (including the weight of the scale platform). For example, if you weigh cows up to 2,000 pounds and your platform weighs 500 pounds, you’ll need load cells with a total capacity of at least 2,500 pounds. Most scales use 4 load cells, so each cell should have a capacity of 625 pounds or more (we recommend adding a 20% safety margin to account for shock loads).

2. Material

Choose stainless steel if your scale is exposed to moisture, manure, or harsh chemicals (like cleaning agents). Alloy steel is a more affordable option for dry, indoor environments (like a veterinary clinic).

3. Protection Rating

Look for a load cell with an IP67 or IP68 rating for outdoor or wet environments. IP67 means the load cell is dust-tight and waterproof, while IP68 means it can be submerged in deeper water for longer periods.

4. Calibration

Make sure the load cell is compatible with your scale’s indicator and can be calibrated easily. Some shear beam load cells come pre-calibrated, which saves time during installation.

5. Brand Reputation

Stick to reputable brands like Mettler Toledo, Rice Lake, or Vishay. These companies offer high-quality load cells with warranties (usually 1-5 years) and good customer support.

Common Myths About Shear Beam Load Cells (Debunked)

There are a few misconceptions about shear beam load cells that we need to clear up:

Myth 1: Shear Beam Load Cells Are Too Expensive

While shear beam load cells may cost more upfront than single-point or compression load cells, their long lifespan and accuracy mean they’re cheaper in the long run. As we saw in the Maplewood Feedlot case study, the savings from reduced maintenance and feed costs far outweigh the initial investment.

Myth 2: They’re Only for Large Farms

Shear beam load cells come in a range of sizes and capacities, making them suitable for small farms too. A low-profile shear beam load cell for a 500-pound capacity scale costs around $150—affordable for even the smallest operations.

Myth 3: They Require Complex Installation

Shear beam load cells are designed for easy installation. Most come with mounting brackets and instructions, and you don’t need specialized tools to set them up. If you’re not comfortable installing them yourself, most farm equipment dealers offer installation services for a reasonable fee.

Conclusion: Shear Beam Load Cells Are the Future of Livestock Weighing

Accurate, durable, and cost-effective—shear beam load cells check all the boxes for livestock scales. They solve the biggest challenges in livestock weighing (off-center loading, harsh environments, heavy loads) and offer long-term savings that boost your profitability.

Whether you’re a small family farm or a large commercial feedlot, investing in shear beam load cells is a smart choice. They’ll help you track animal growth, optimize feed rations, stay compliant with regulations, and reduce maintenance costs. And with real-world success stories from farms across the country, it’s clear that shear beam load cells are more than just a trend—they’re a reliable solution for modern livestock operations.

If you’re ready to upgrade your scale and start reaping the benefits of shear beam load cells, contact a reputable scale dealer today. They can help you choose the right load cell for your needs and ensure your scale is installed correctly. Your bottom line (and your animals) will thank you.