In the world of engineering, manufacturing, and even everyday technology, precision is often the difference between success and failure. Whether you’re driving a car, using a power tool, or operating industrial machinery, understanding the forces at play—specifically, torque—is critical. Torque, the rotational equivalent of linear force, measures how much a force acting on an object causes it to rotate around an axis. To measure this force accurately, engineers rely on a specialized device: the torque sensor. In this blog, we’ll explore what a torque sensor is, its various types, how it works, and its wide-ranging applications across industries.

Defining Torque: The Foundation of Torque Sensing

Before diving into torque sensors, let’s clarify what torque is. Torque (symbolized as τ, the Greek letter tau) is calculated as the product of the force applied (F) and the perpendicular distance from the axis of rotation to the point where the force is applied (r). Mathematically, this is expressed as τ = r × F × sin(θ), where θ is the angle between the force vector and the lever arm. In simpler terms, torque is what makes objects spin: think of tightening a bolt with a wrench, where a longer wrench (greater r) or more force (greater F) increases the torque applied.

Why is measuring torque important? In mechanical systems, torque directly impacts performance, efficiency, and safety. For example, in an electric vehicle, the motor’s torque output determines acceleration and towing capacity. In manufacturing, over-tightening a bolt due to unmeasured torque can damage components, while under-tightening can lead to structural failure. Torque sensors provide the data needed to monitor, control, and optimize these processes, making them indispensable in modern engineering.

What is a Torque Sensor?

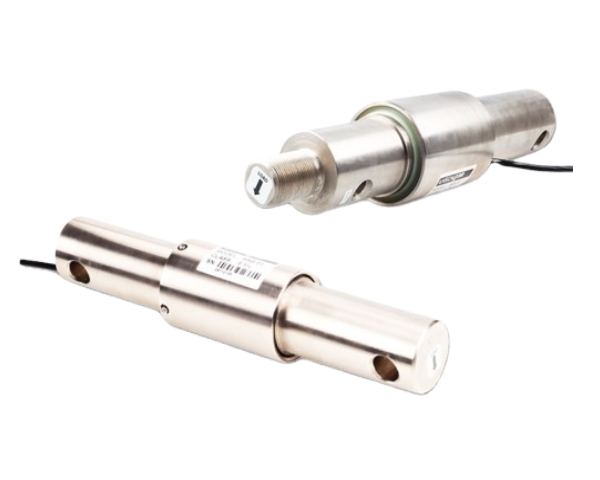

A torque sensor, also known as a torque transducer or torque meter, is a device designed to measure and convert torque into an electrical signal that can be read, recorded, or used for control purposes. It acts as a bridge between the mechanical world of rotating components and the digital world of data analysis and automation. Torque sensors are used in both static (non-rotating) and dynamic (rotating) applications, and their design varies based on the specific use case, required accuracy, and environmental conditions.

At its core, a torque sensor works by detecting the deformation (strain) that occurs in a material when torque is applied. Most materials, when subjected to torque, twist slightly. This twist is proportional to the applied torque, following Hooke’s Law (within the material’s elastic limit). The sensor measures this deformation and converts it into an electrical signal using a transducer, such as a strain gauge.

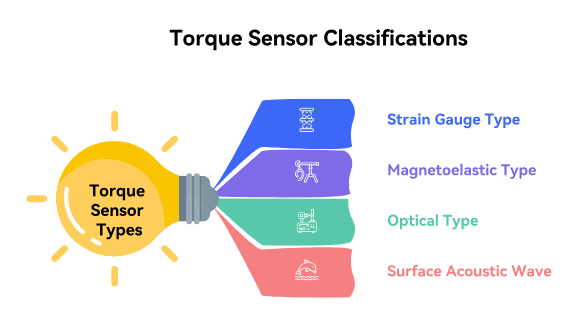

Types of Torque Sensors

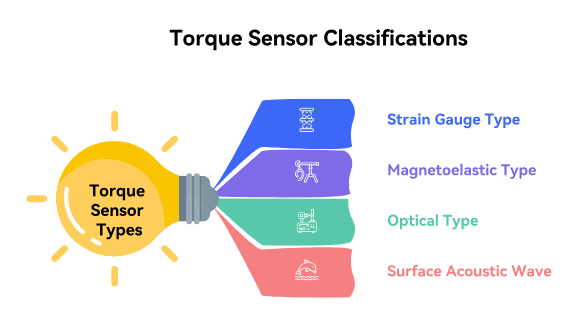

In several types, each suited to different applications. The primary distinction is between static and dynamic sensors, but they can also be categorized by their working principle, such as strain gauge-based, optical, capacitive, or piezoelectric sensors. Let’s explore the most common types:

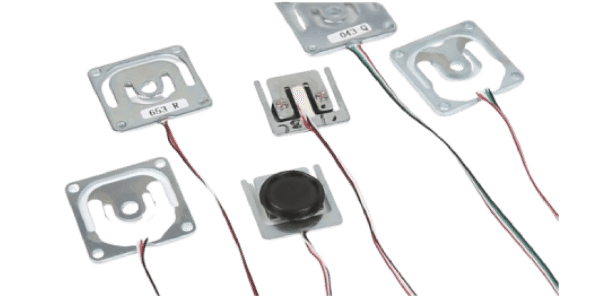

1. Strain Gauge Torque Sensors

Strain gauge torque sensors are the most widely used type due to their high accuracy, reliability, and versatility. They work by attaching thin, flexible strain gauges to a torque-sensitive element (often a metal shaft or beam) that deforms under torque.

How Strain Gauges Work:

A strain gauge is a small device made of a conductive material (typically a metal foil or semiconductor) arranged in a grid pattern. When the material it’s attached to stretches or compresses (strain), the length and cross-sectional area of the strain gauge change, altering its electrical resistance. This change in resistance is minuscule (often in the micro-ohm range) but can be measured using a Wheatstone bridge circuit, which amplifies the signal for analysis.

Static vs. Dynamic Strain Gauge Sensors:

-

Static Torque Sensors: Used for non-rotating applications, such as measuring the torque required to tighten a bolt with a fixed wrench. The strain gauges are directly wired to the measurement system, as there’s no rotation to complicate signal transmission.

-

Dynamic Torque Sensors: Used for rotating components, such as a car’s driveshaft or a wind turbine’s rotor. Here, the challenge is transmitting the signal from the rotating strain gauges to the stationary measurement system. This is typically done using slip rings (mechanical contacts), wireless telemetry, or rotary transformers (inductive coupling).

-

Slip rings, while simple, can introduce friction and wear, limiting their use in high-speed or long-duration applications. Wireless telemetry, which uses radio waves or infrared to transmit data, avoids physical contact but may be affected by electromagnetic interference (EMI). Rotary transformers use magnetic fields to transfer power and signals inductively, offering a balance of reliability and low maintenance, making them common in industrial settings.

2. Optical Torque Sensors

Optical torque sensors use light to measure the twist in a rotating component, offering high precision and immunity to electromagnetic interference—an advantage in environments with strong electrical noise, such as near motors or power lines.

Working Principle:

An optical torque sensor typically consists of a light source (e.g., a laser or LED), a rotating element with optical markers (such as gratings or encoder disks), and a stationary light detector. When torque is applied, the rotating element twists, causing a shift in the position of the optical markers relative to the detector. This shift is measured as a phase difference or change in light intensity, which is then converted into a torque reading.

For example, in a laser-based optical sensor, two gratings are placed on either end of a torque-sensitive shaft. When the shaft twists, the gratings move relative to each other, creating an interference pattern (moiré pattern) that changes with the amount of twist. The detector measures this pattern and calculates torque based on the displacement.

Optical sensors are often used in high-precision applications, such as aerospace testing or laboratory research, where accuracy and resistance to EMI are critical. However, they can be more expensive and sensitive to environmental factors like dust or vibration compared to strain gauge sensors.

3. Piezoelectric Torque Sensors

Piezoelectric torque sensors utilize the piezoelectric effect, where certain materials (e.g., quartz or ceramics) generate an electrical charge when subjected to mechanical stress. Unlike strain gauge sensors, which measure static strain, piezoelectric sensors are ideal for dynamic torque measurements (rapidly changing torque) because they produce a charge proportional to the rate of strain change.

Working Principle:

When torque is applied to a piezoelectric sensor, the material deforms, creating a charge separation across its surfaces. This charge is collected by electrodes and converted into a voltage signal using a charge amplifier. Piezoelectric sensors are compact, rugged, and capable of measuring high-frequency torque fluctuations, making them suitable for applications like engine testing, where torque varies rapidly during combustion cycles.

However, they have limitations: they cannot measure static torque (since the charge dissipates over time), and their output is sensitive to temperature changes, requiring compensation circuits for accuracy.

4. Capacitive Torque Sensors

Capacitive torque sensors measure torque by detecting changes in capacitance caused by the deformation of a rotating element. Capacitance, the ability of a system to store an electric charge, depends on the area of the capacitor plates, the distance between them, and the dielectric material between them. In torque sensing, the “plates” are typically two concentric cylinders or plates attached to a torque-sensitive shaft. When the shaft twists, the distance or overlap between the plates changes, altering the capacitance. This change is then converted into a torque reading.

Capacitive sensors are known for their high sensitivity and low power consumption, but they are often more complex to manufacture and can be affected by environmental factors like humidity, which changes the dielectric properties of air. They are used in specialized applications where precision and miniaturization are key, such as medical devices or small robotics.

How Does a Torque Sensor Work? A Deep Dive into Strain Gauge Technology

While there are multiple types of torque sensors, strain gauge-based sensors are the most common, so let’s focus on their operation to understand the general principles of torque sensing.

Step 1: The Torque-Sensitive Element

The heart of a strain gauge torque sensor is the torque-sensitive element, often called the “shaft” or “torque tube.” This is a cylindrical or beam-shaped component made of a material with known mechanical properties (e.g., high-strength steel or aluminum alloy). The material is chosen for its elasticity (ability to return to its original shape after deformation) and linear stress-strain relationship, ensuring that the deformation is proportional to the applied torque.

When torque is applied to the element, it undergoes torsional deformation (twisting). For example, if you hold a ruler at both ends and twist it, the ruler bends slightly—this is torsional deformation. In the sensor, the amount of twist is tiny (often measured in micro-radians) but measurable with strain gauges.

Step 2: Strain Gauges and Bonding

Strain gauges are bonded to the surface of the torque-sensitive element in a specific pattern to detect torsional strain. Since torque causes both tension and compression in the material (the outer surface of the shaft stretches on one side and compresses on the opposite side), strain gauges are placed at 45-degree angles to the shaft’s axis. This orientation maximizes their sensitivity to torsional strain while minimizing sensitivity to other forces, such as axial load (thrust) or bending.

The bonding process is critical: the strain gauge must be securely attached to ensure that all deformation of the element is transferred to the gauge. Special adhesives are used to bond the gauge, and the surface of the element is often prepared (e.g., polished and cleaned) to ensure optimal adhesion.

Step 3: Wheatstone Bridge Circuit

To measure the small changes in resistance from the strain gauges, they are connected in a Wheatstone bridge configuration. A Wheatstone bridge is an electrical circuit with four resistive arms (in this case, strain gauges), a voltage source, and a voltage detector. When the bridge is balanced (all resistances equal), the detector reads zero voltage. When torque is applied, the strain gauges on the tension side stretch (increasing resistance) and those on the compression side compress (decreasing resistance), unbalancing the bridge and producing a voltage output proportional to the applied torque.

Most strain gauge torque sensors use a full-bridge configuration, with four strain gauges: two in tension and two in compression. This setup provides higher sensitivity, temperature compensation (since all gauges are affected equally by temperature changes), and cancellation of unwanted forces like bending or axial load.

Step 4: Signal Conditioning and Output

The voltage output from the Wheatstone bridge is very small (typically millivolts), so it must be amplified using a signal conditioner. The signal conditioner also filters out noise, compensates for temperature drift, and converts the analog signal into a digital format (e.g., via an analog-to-digital converter, ADC) for processing by a computer, PLC (programmable logic controller), or display unit.

In dynamic applications (rotating shafts), the challenge is transmitting the signal from the rotating strain gauges to the stationary signal conditioner. As mentioned earlier, this is done using slip rings, wireless telemetry, or rotary transformers:

-

Slip Rings: Brushes in contact with rotating rings transfer the signal. Simple but prone to wear and noise.

-

Wireless Telemetry: A small transmitter on the rotating shaft sends data via radio waves to a stationary receiver. Eliminates contact but requires power (batteries or inductive coupling).

-

Rotary Transformers: Inductive coils on the rotating and stationary parts transfer power and signal without contact, offering high reliability for industrial use.

Step 5: Calibration

For a torque sensor to provide accurate readings, it must be calibrated. Calibration involves applying known torque values to the sensor and recording the corresponding output signals. This establishes a calibration curve, which is used to convert future output signals into torque measurements. Calibration is typically done in a controlled laboratory using precision weights or torque standards, and it may need to be repeated periodically to account for wear, material fatigue, or environmental changes.

Applications of Torque Sensors

Torque sensors are used across a wide range of industries, from automotive and aerospace to manufacturing and healthcare. Here are some key applications:

1. Automotive Industry

The automotive sector is one of the largest users of torque sensors. They are used in:

-

Engine Testing: Measuring the torque output of internal combustion engines or electric motors to optimize fuel efficiency and performance.

-

Transmission Development: Testing gearbox torque to ensure smooth shifting and durability.

-

Electric Power Steering (EPS): In EPS systems, torque sensors detect the driver’s steering input torque, allowing the system to apply the correct amount of electric assist. This improves fuel efficiency (compared to hydraulic systems) and enables features like lane-keeping assist.

-

Tire Testing: Measuring the torque required to rotate tires under different conditions (e.g., load, speed) to evaluate traction and rolling resistance.

2. Manufacturing and Robotics

In manufacturing, torque sensors ensure precision and consistency in assembly processes:

-

Bolt Tightening: In automotive and aerospace assembly lines, torque sensors in power tools (e.g., torque wrenches) ensure bolts are tightened to exact specifications, preventing over-tightening (damage) or under-tightening (loosening).

-

Robotics: Robotic arms use torque sensors to “feel” the force applied during tasks like gripping delicate objects or assembling components, enabling precise and safe interaction with the environment (a concept known as “force feedback”).

-

Quality Control: Testing the torque required to operate products (e.g., bottle caps, door hinges) to ensure they meet usability and durability standards.

3. Aerospace and Defense

In aerospace, where safety and reliability are paramount, torque sensors are used in:

-

Aircraft Engines: Monitoring turbine and propeller torque to ensure engines operate within safe limits and detect potential failures.

-

Rocket Testing: Measuring the torque of rocket motor thrust vectoring systems, which control the rocket’s direction during launch.

-

Helicopters: The main rotor’s torque output affects lift and maneuverability; sensors help pilots maintain stability and prevent engine overload.

4. Renewable Energy

Renewable energy systems, such as wind turbines and solar trackers, rely on torque sensors to optimize efficiency:

-

Wind Turbines: Torque sensors measure the torque from the rotor blades to the gearbox and generator. This data is used to adjust blade pitch, maximizing power output while preventing damage during high winds.

-

Solar Trackers: Torque sensors ensure solar panels rotate smoothly to follow the sun, reducing mechanical stress and improving energy capture.

5. Medical Devices

In healthcare, torque sensors are used in applications requiring precision and safety:

-

Surgical Tools: Robotic surgical systems (e.g., da Vinci) use torque sensors to provide haptic feedback to surgeons, simulating the feel of tissue resistance and preventing excessive force that could cause injury.

-

Prosthetics: Torque sensors in prosthetic limbs detect the user’s movement intent, allowing for more natural and responsive control.

6. Marine and Offshore

In marine applications, torque sensors monitor propulsion systems for efficiency and maintenance:

-

Ship Engines: Measuring torque from the engine to the propeller helps optimize fuel consumption and detect issues like propeller fouling (buildup of marine growth, which increases torque demand).

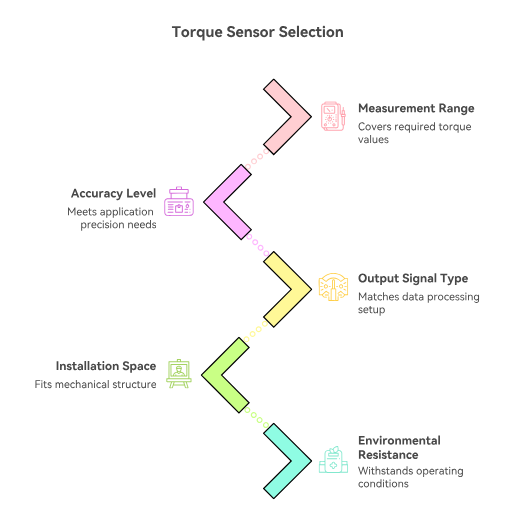

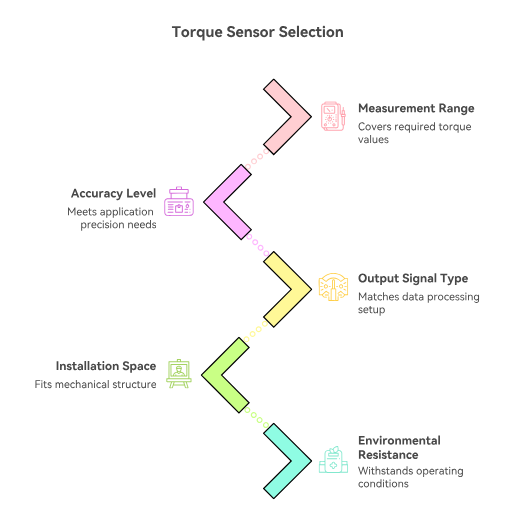

Factors to Consider When Choosing a Torque Sensor

-

Selecting the right torque sensor depends on several factors:

1. Torque Range

The sensor must be rated for the minimum and maximum torque expected in the application. Using a sensor outside its range can lead to damage or inaccurate readings.

2. Accuracy and Resolution

Accuracy is the closeness of a measurement to the true value, while resolution is the smallest torque increment that can be detected. High-precision applications (e.g., aerospace testing) require sensors with accuracy of ±0.1% or better, while industrial applications may accept ±1% accuracy.

3. Static vs. Dynamic Measurement

Static sensors are for non-rotating components (e.g., bolt tightening), while dynamic sensors are for rotating shafts (e.g., engine testing). Dynamic sensors require signal transmission solutions (slip rings, wireless, etc.).

4. Environmental Conditions

Consider temperature, humidity, vibration, and exposure to chemicals or contaminants. For harsh environments (e.g., manufacturing plants), sensors with rugged enclosures (IP67/IP68 ratings) and temperature compensation are necessary.

5. Mounting and Installation

The sensor must fit within the mechanical system, considering shaft diameter, length, and mounting style (flange, keyed, or splined connections). Some sensors are designed for inline mounting (series with the shaft), while others are attached externally.

6. Output Signal

Sensors may output analog signals (voltage, current) or digital signals (RS485, CAN bus, Ethernet). The choice depends on the data acquisition system used (e.g., PLCs often use analog inputs, while computers may prefer digital).

7. Cost

High-accuracy sensors with advanced features (e.g., wireless telemetry) are more expensive. Balance cost with the application’s requirements—over-specifying can increase costs unnecessarily, while under-specifying risks poor performance.

Challenges and Future Trends in Torque Sensing

While torque sensors are highly effective, they face challenges in certain applications:

-

High-Speed Rotation: At very high speeds (e.g., gas turbines), centrifugal forces can affect sensor accuracy, requiring specialized designs.

-

Miniaturization: In small devices (e.g., medical tools), sensors must be tiny while maintaining accuracy, driving demand for microfabrication techniques.

-

EMI and Noise: In industrial environments with high electrical noise, signal interference can corrupt readings, requiring better shielding and filtering.

Looking to the future, several trends are shaping torque sensor development:

-

Smart Sensors: Integration of IoT (Internet of Things) capabilities, allowing sensors to transmit data wirelessly to cloud platforms for real-time monitoring and predictive maintenance.

-

MEMS Technology: Micro-electromechanical systems (MEMS) are enabling smaller, cheaper, and more rugged torque sensors by miniaturizing strain gauges and electronics on a single chip.

-

Energy Harvesting: For wireless sensors, energy harvesting (e.g., using vibration or thermal energy) could eliminate the need for batteries, improving reliability.

-

AI and Machine Learning: Combining torque sensor data with AI algorithms to predict failures, optimize performance, and enable adaptive control in complex systems.

Conclusion

Torque sensors are the unsung heroes of modern engineering, enabling the precise measurement and control of rotational forces across industries. From electric vehicles to surgical robots, they ensure safety, efficiency, and reliability in countless applications. By detecting the subtle twists in materials and converting them into actionable data, torque sensors bridge the gap between mechanical systems and digital

HOT keyword: