Load cells are critical components in industrial, commercial, and even residential applications, converting physical force—such as weight, tension, or compression—into measurable electrical signals. Whether you’re setting up a weighing system in a manufacturing plant, a material testing rig in a lab, or a custom load monitoring device, proper installation is key to ensuring accuracy, reliability, and longevity. A poorly installed load cell can lead to erroneous readings, equipment damage, or safety hazards. In this comprehensive guide, we’ll walk you through the step-by-step process of installing a load cell, from pre-installation planning to post-installation testing, along with best practices to avoid common pitfalls.

Understanding Load Cells: Types and Applications

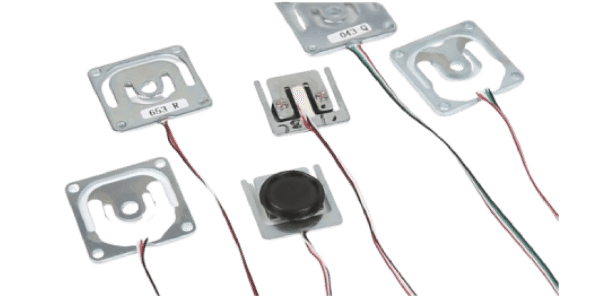

Before diving into installation, it’s essential to understand the basics of load cells, as different types require specific mounting and handling techniques. Load cells come in various designs, each optimized for particular forces and environments:

-

Strain Gauge Load Cells: The most common type, these use strain gauges bonded to a metal structure (e.g., a beam or column). When force is applied, the structure deforms, changing the resistance of the strain gauges, which is measured as a voltage change. They are versatile and used in scales, industrial machinery, and material testing.

-

Pneumatic Load Cells: These use air pressure to balance applied force, making them suitable for hazardous environments due to their lack of electrical components. They are often used in food processing or chemical plants.

-

Hydraulic Load Cells: Similar to pneumatic load cells but use hydraulic fluid to measure force. They are robust and ideal for heavy-duty applications like construction equipment.

-

Capacitive Load Cells: These measure changes in capacitance due to force-induced displacement, offering high sensitivity for precision applications like medical devices.

For the purposes of this guide, we’ll focus on strain gauge load cells, as they are the most widely used and require careful installation to maintain accuracy.

Pre-Installation Planning: Key Considerations

Installing a load cell is not a “plug-and-play” task. Proper planning ensures that the load cell operates within its specifications and integrates seamlessly with the system. Here are the critical steps to take before picking up a wrench:

1. Define the Application Requirements

Start by clarifying the purpose of the load cell:

-

Force Type: Will it measure tension (pulling), compression (pushing), or both? For example, a crane scale uses tension, while a floor scale uses compression.

-

Capacity: What is the maximum force the load cell will encounter? Choose a load cell with a capacity 20-30% higher than the expected maximum load to avoid overloading, which can cause permanent damage.

-

Accuracy Class: Industrial applications may require ±0.1% accuracy, while lab testing might need ±0.01%. Check the load cell’s datasheet for its accuracy class (e.g., C3 for industrial, C6 for high precision).

-

Environmental Conditions: Will the load cell be exposed to moisture, dust, extreme temperatures, or corrosive substances? Select a load cell with appropriate protection (e.g., IP67 for water resistance, IP68 for submersion) and material (stainless steel for corrosion resistance, aluminum for lightweight applications).

2. Select the Right Load Cell and Accessories

Based on the above requirements, choose a load cell model that matches your needs. Additionally, gather the necessary accessories:

-

Mounting Hardware: Brackets, bolts, and washers must be made of materials compatible with the load cell (e.g., stainless steel to prevent galvanic corrosion) and rated for the expected load.

-

Cables: Use shielded, twisted-pair cables to minimize electromagnetic interference (EMI), which can distort readings. The cable length should be as short as possible to reduce signal loss; if longer cables are needed, use a signal conditioner with amplification.

-

Signal Conditioner/Amplifier: Strain gauge load cells produce weak signals (typically millivolts), so a conditioner converts this signal to a readable format (e.g., 4-20mA, 0-10V) for displays or data loggers.

-

Junction Box: If using multiple load cells (e.g., in a platform scale with four load cells), a junction box combines their signals and balances output.

3. Inspect the Installation Site

The mounting location must be stable, level, and free from external forces that could interfere with measurements:

-

Stability: The base or structure supporting the load cell must be rigid. A flexible or vibrating base will cause erratic readings. For example, a floor scale should be mounted on a concrete slab, not a wooden floor.

-

Alignment: The load cell must align with the direction of the applied force. Misalignment (even by a few degrees) creates side loads, which strain the load cell and reduce accuracy.

-

Space: Ensure there is enough room to install the load cell, cables, and accessories without bending or stretching components. Avoid tight spaces that make maintenance difficult.

4. Calibrate Tools and Safety Precautions

-

Tools: Use calibrated torque wrenches to tighten bolts to the manufacturer’s specifications—over-tightening can strain the load cell, while under-tightening can cause slippage. A level (spirit or digital) ensures the mounting surfaces are flat.

-

Safety: If working with heavy loads or in elevated areas, use proper PPE (gloves, safety glasses, hard hat). Disconnect power to nearby electrical equipment to avoid触电 (electric shock) during installation.

Step-by-Step Installation Guide for Strain Gauge Load Cells

Now that you’ve planned thoroughly, let’s walk through the installation process. We’ll use a compression load cell in a floor scale as an example, but the principles apply to other strain gauge load cells with adjustments for tension or mounting orientation.

Step 1: Prepare the Mounting Surface

The load cell must rest on a flat, clean, and rigid surface to ensure even force distribution.

Clean the Surface: Remove dirt, rust, or paint from the mounting plate or structure using a wire brush or sandpaper. Any debris can create uneven contact, leading to measurement errors.

Check Flatness: Use a straightedge or digital level to verify that the surface is flat within 0.001 inches per inch (0.025mm per cm). If not, shim with thin metal plates (e.g., stainless steel shims) to level the surface. Avoid using rubber or plastic shims, as they compress under load and introduce variability.

Step 2: Mount the Load Cell Base (Compression Applications)

For compression load cells, the base plate (where the load cell sits) must be securely fastened to the supporting structure.

Position the Base Plate: Align the base plate with the load path (the direction of the force). For a floor scale, this means centering the base plate under the scale platform.

Secure the Base Plate: Use bolts rated for the load, ensuring they are long enough to penetrate the supporting structure (e.g., concrete anchors for a slab). Tighten the bolts in a crisscross pattern to distribute force evenly and prevent warping.

Step 3: Install the Load Cell

Handle the load cell with extreme care—strain gauges are delicate and can be damaged by dropping, bending, or excessive heat.

Inspect the Load Cell: Check for visible damage, such as dents, cracks, or loose wires. Verify that the strain gauge leads are intact and the cable is not frayed.

Place the Load Cell on the Base Plate: For compression load cells, the load cell’s bottom surface should rest squarely on the base plate. Use a thin layer of anti-seize compound (e.g., graphite-based) on the contact surfaces to prevent galling (metal-to-metal adhesion) without adding thickness that could compress under load.

Align the Load Cell: Ensure the load cell’s axis (marked on the housing) is parallel to the direction of the applied force. Use a plumb bob or laser level for precision. Misalignment of just 1 degree can reduce accuracy by 0.17%, according to industry standards.

Step 4: Attach the Load Cell to the Upper Structure (Compression)

The upper structure (e.g., the scale platform) transfers the load to the load cell.

Position the Upper Mounting Plate: Place the upper plate on top of the load cell, ensuring it is centered and aligned with the load cell’s top surface.

Secure the Upper Plate: Use bolts to fasten the upper plate to the load cell, but do not fully tighten them yet. Leave a small gap to allow for final alignment.

Step 5: Route and Connect the Cable

The load cell’s cable is a critical component—poor routing can introduce noise or damage the wires.

Route the Cable Away from EMI Sources: Keep the cable away from motors, transformers, or power lines, which emit electromagnetic fields. If crossing power cables is unavoidable, cross them at a 90-degree angle to minimize interference.

Avoid Sharp Bends and Tension: The cable should have a minimum bend radius (specified in the datasheet, typically 10-15 times the cable diameter) to prevent damage to internal wires. Use cable clips or conduits to secure the cable, leaving slack to avoid pulling on the load cell’s terminals.

Connect the Cable to the Load Cell: Most strain gauge load cells have four or six wires: excitation (+EXC), excitation (-EXC), signal (+SIG), signal (-SIG), and optionally, sense wires (+SEN, -SEN) for long cables to compensate for voltage drop. Refer to the load cell’s wiring diagram to connect the cable correctly. Use heat-shrink tubing or cable glands to seal the connection and protect against moisture.

Step 6: Install Signal Conditioning and Wiring

The load cell’s low-voltage signal (typically 2-3mV/V) must be amplified and converted to a usable format.

Mount the Signal Conditioner: Place the conditioner in a dry, temperature-stable location (ideally 20-25°C/68-77°F). Avoid mounting it near heat sources like motors or direct sunlight, as temperature fluctuations affect electronics.

Wire the Load Cell to the Conditioner: Connect the load cell’s cable to the conditioner’s input terminals, following the wiring diagram. If using sense wires, connect them to the conditioner’s sense terminals to ensure the excitation voltage at the load cell remains constant.

Ground the System: Proper grounding prevents noise and protects against electrical surges. Connect the load cell’s cable shield to the conditioner’s ground terminal, and ground the conditioner to the system’s earth ground. Use a single-point ground to avoid ground loops (circulating currents that cause noise).

Step 7: Secure All Fasteners

Once alignment is confirmed, tighten the load cell’s mounting bolts gradually and evenly.

Torque the Bolts: Use a calibrated torque wrench to tighten the bolts to the manufacturer’s specifications (e.g., 15 ft-lbs for 1/4-inch stainless steel bolts). Over-tightening can strain the load cell, while under-tightening allows movement.

Recheck Alignment: After tightening, recheck the load cell’s alignment—bolting can sometimes shift the position. Adjust as needed.

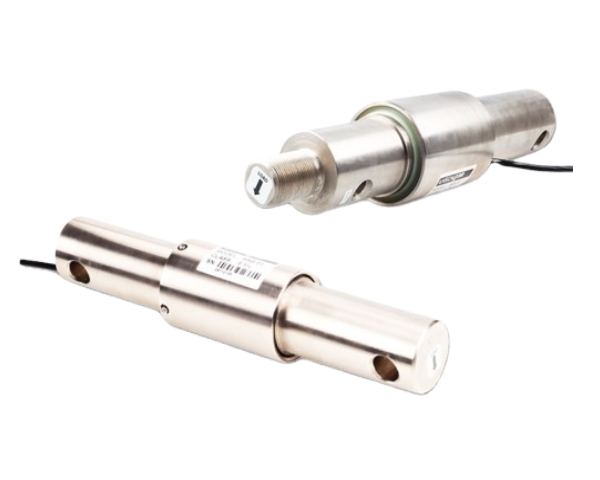

Tension Load Cell Installation: Special Considerations

Tension load cells (e.g., those used in crane scales or winch systems) require slightly different mounting techniques to ensure the load is applied axially. Here’s how to adapt the process:

Use Clevis or Eye Bolts: Tension load cells often have threaded ends or eyes for attachment. Use clevises (U-shaped brackets) or eye bolts to connect the load cell between two points (e.g., the crane hook and the load).

Prevent Side Loads: In tension applications, side loads are more likely due to swinging loads. Use swivels or spherical bearings to allow the load cell to rotate freely, ensuring the force remains axial.

Avoid Over-Tightening Threaded Connections: Threaded tension load cells can be damaged by over-tightening, which stretches the housing and preloads the strain gauges. Use a torque wrench and follow the manufacturer’s torque specs for threaded ends.

Post-Installation Testing and Calibration

Installing the load cell is only half the battle—testing and calibration ensure it provides accurate readings.

1. Initial System Check

Before applying load, perform a visual and electrical check:

Visual Inspection: Ensure all cables are secure, fasteners are tight, and there are no signs of damage.

Electrical Check: Power on the system and measure the output signal with a multimeter. With no load, the signal should be near zero (for compression) or the tare value (preload). If the signal is erratic, check for loose connections or EMI.

2. Apply Preload (If Required)

Some load cells, especially those in tension, require a small preload to ensure the strain gauges are in their linear range. For example, a crane scale load cell might need 5-10% of its capacity in preload to eliminate slack in the system.

3. Calibrate the Load Cell

Calibration compares the load cell’s output to known reference weights or forces. This is critical because installation stresses (e.g., bolt tension, temperature) can shift the zero point or sensitivity.

Zero Calibration: With no load applied, adjust the signal conditioner’s zero potentiometer or use software to set the output to 0% of full scale.

Span Calibration: Apply a known load (e.g., a certified weight) equal to 100% of the load cell’s capacity. Adjust the conditioner’s span potentiometer to set the output to 100% of full scale.

Multi-Point Calibration: For higher accuracy, calibrate at 25%, 50%, 75%, and 100% of capacity. The readings should form a straight line (linearity error should be within the load cell’s specs).

4. Test Under Load

Apply the maximum expected load and monitor the output for stability. Check for:

Hysteresis: The difference in output when loading and unloading the same weight. It should be within the load cell’s hysteresis specification (e.g., ±0.02%).

Creep: The change in output when a constant load is applied over time (e.g., 0.01% of full scale per hour). If creep is excessive, check for loose connections or overloading.

Best Practices for Long-Term Reliability

To ensure the load cell performs well for years, follow these maintenance and operational guidelines:

1. Protect Against Environmental Factors

Moisture: Use cable glands with O-rings to seal cable entries. For outdoor installations, enclose the signal conditioner in a weatherproof box.

Temperature: If the load cell is exposed to extreme temperatures, use thermal insulation or heat sinks. Some load cells have temperature compensation (TC) to minimize drift, but large swings can still affect accuracy.

Vibration: Use vibration dampeners (e.g., rubber mounts) if the system is subject to mechanical vibration, which can fatigue the load cell and cause noise.

2. Handle Cables with Care

Avoid Stretching or Kinking: Cables should have slack to accommodate movement (e.g., in a moving crane scale). Use cable ties with looped ends to prevent cutting into the cable.

Inspect Cables Regularly: Check for abrasion, rodent damage, or corrosion. Replace damaged cables immediately, as they can introduce noise or cause the load cell to fail.

3. Perform Routine Maintenance

Clean the Load Cell: Wipe the load cell with a damp cloth to remove dirt or debris. For corrosive environments, use a mild detergent (e.g., soap and water) and rinse thoroughly.

Re-Calibrate Annually: Even well-installed load cells drift over time due to aging components or environmental changes. Schedule annual calibration with a certified service provider to maintain accuracy.

Check Fasteners: Periodically inspect mounting bolts for tightness, especially in high-vibration applications.

4. Avoid Overloading

Never exceed the load cell’s rated capacity. Install overload stops (mechanical limits) to prevent accidental overloading. For example, a floor scale might have bumpers that limit platform movement if the load exceeds the load cell’s capacity.

Troubleshooting Common Installation Issues

Even with careful planning, problems can arise. Here are solutions to common issues:

Erratic Readings: Check for loose connections, EMI, or ground loops. Move the cable away from power lines, or add a ferrite core (a magnetic ring) to the cable to suppress noise.

Zero Drift: Temperature changes or preload shifts can cause zero drift. Re-zero the system and ensure the load cell is at ambient temperature. If drift persists, the strain gauges may be damaged.

Low Sensitivity: This could indicate a broken strain gauge or incorrect wiring. Use a multimeter to check the resistance of the strain gauge bridge (typically 350 ohms for standard load cells). A reading of infinity indicates a broken wire.

Non-Linear Output: Misalignment or uneven loading is likely the cause. Recheck the load cell’s alignment and ensure the mounting surfaces are flat.

Conclusion

Installing a load cell is a precision task that requires careful planning, attention to detail, and adherence to best practices. By defining requirements, selecting the right components, ensuring proper alignment, and following calibration procedures, you can ensure accurate, reliable measurements for years to come. Remember, the goal is to minimize external influences—misalignment, vibration, temperature, and noise—that can compromise performance. With the steps outlined in this guide, you’ll be well-equipped to install a load cell that meets your application’s needs and stands the test of time.

Whether you’re a seasoned engineer or a DIY enthusiast, taking the time to do it right will save you from costly repairs, inaccurate data, and safety risks. So, grab your torque wrench, double-check your alignment, and get ready to measure force with confidence.