In the world of industrial automation, manufacturing, and scientific research, accurate measurement of force and weight is not just a convenience—it’s a necessity. From ensuring product quality on assembly lines to monitoring structural integrity in bridges, the ability to quantify force with precision can mean the difference between success and failure, safety and disaster. Among the many tools designed for this purpose, the S-type load cell stands out as a versatile, reliable, and widely used solution. Despite its unassuming name and simple design, this device plays a critical role in countless applications, often operating behind the scenes to provide the data that drives decision-making. In this blog, we’ll take a deep dive into S-type load cells, exploring their design, working principles, advantages, applications, and key considerations for selection and maintenance. By the end, you’ll understand why these small but mighty sensors are indispensable in modern engineering and technology.

What is an S-Type Load Cell?

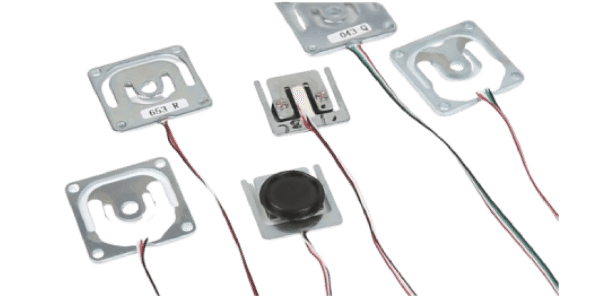

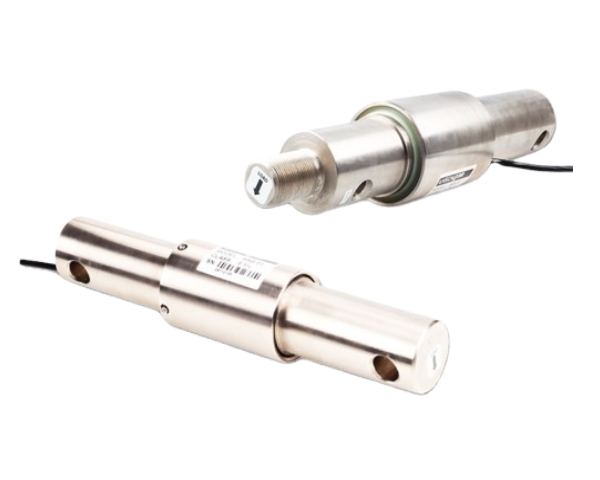

At its core, a load cell is a transducer—a device that converts one form of energy (in this case, mechanical force) into an electrical signal that can be measured and analyzed. Load cells come in various shapes and sizes, each tailored to specific applications. The S-type load cell, named for its distinctive “S” or “Z” shape when viewed from the side, is a type of strain gauge load cell. Strain gauge load cells work by measuring the deformation (strain) of a metal element under load, which is then converted into an electrical output proportional to the applied force.

The S-shape of these load cells is not arbitrary; it’s a carefully engineered design that maximizes sensitivity while maintaining structural strength. The central portion of the “S” is thinner than the top and bottom flanges, creating a region where strain is concentrated when force is applied. This concentration of strain allows for precise measurement, even with small loads, while the thicker flanges provide stability and support for mounting. Most S-type load cells are made from high-strength alloys like stainless steel or aluminum, chosen for their durability, resistance to corrosion, and consistent mechanical properties—all essential for reliable long-term performance.

How Do S-Type Load Cells Work?

To understand the inner workings of an S-type load cell, we must first grasp the basics of strain gauge technology. A strain gauge is a small, flexible device composed of a thin wire or foil arranged in a grid pattern on a backing material (usually plastic). When the material to which the strain gauge is bonded is stretched or compressed, the grid deforms, changing its electrical resistance. This change in resistance is minute but measurable, and it forms the basis of how load cells convert force into an electrical signal.

In an S-type load cell, multiple strain gauges are bonded to the thin central section of the S-shaped element. Typically, four strain gauges are used, arranged in a Wheatstone bridge configuration—a circuit that amplifies small changes in resistance to produce a measurable voltage output. The Wheatstone bridge consists of four resistors (in this case, the strain gauges) connected in a diamond shape, with a voltage applied across two opposite corners and the output measured across the other two.

When a force is applied to the load cell (either tension, compression, or both), the S-shaped element deforms. For example, if tension is applied (pulling the top and bottom flanges apart), the central section stretches, causing the strain gauges on the outer surfaces to elongate (increasing their resistance) and those on the inner surfaces to compress (decreasing their resistance). Conversely, in compression (pushing the flanges together), the outer gauges compress and the inner gauges stretch. These opposing changes in resistance unbalance the Wheatstone bridge, resulting in a voltage output that is directly proportional to the applied force.

This output voltage is typically very small (in the millivolt range), so it must be amplified using a signal conditioner or transmitter before it can be read by a data acquisition system, display unit, or controller. The signal conditioner also compensates for environmental factors like temperature, which can affect the resistance of the strain gauges and the mechanical properties of the load cell element. Modern load cells often include built-in temperature compensation circuits to ensure accuracy across a wide range of operating conditions.

Key Components of an S-Type Load Cell

While the basic design of S-type load cells is standardized, several key components work together to ensure their functionality:

1. The Load Cell Element (Spring Element)

The S-shaped metal structure is the heart of the load cell. As discussed, its geometry is optimized to concentrate strain in the central region, where the strain gauges are mounted. The material of the element is critical—stainless steel is preferred for harsh environments (e.g., food processing, marine applications) due to its corrosion resistance, while aluminum is lighter and more cost-effective for lower-load applications where weight is a concern.

2. Strain Gauges

These are the sensing elements that convert mechanical strain into electrical resistance change. High-quality load cells use precision strain gauges with tight tolerances to ensure consistency. The gauges are carefully bonded to the load cell element using specialized adhesives that maintain a strong bond even under repeated loading and temperature fluctuations.

3. Wheatstone Bridge Circuit

The four strain gauges are wired into a Wheatstone bridge to amplify the signal and improve accuracy. The bridge configuration cancels out common-mode errors (e.g., temperature-induced changes affecting all gauges equally) and provides a linear output proportional to force.

4. Encapsulation and Protection

To shield the internal components from moisture, dust, and physical damage, S-type load cells are often encapsulated in a protective coating or housed in a sealed casing. IP (Ingress Protection) ratings are used to indicate the level of protection—for example, an IP67 rating means the load cell is dust-tight and can withstand temporary immersion in water, making it suitable for industrial environments.

5. Mounting Hardware

The top and bottom flanges of the S-type load cell are designed with holes or threads for mounting. Proper mounting is crucial for accurate measurement, as misalignment can introduce errors by causing bending or torsion in the load cell element. Many manufacturers provide guidelines for mounting torque, alignment, and the use of spherical washers to ensure that force is applied axially (along the central axis of the load cell).

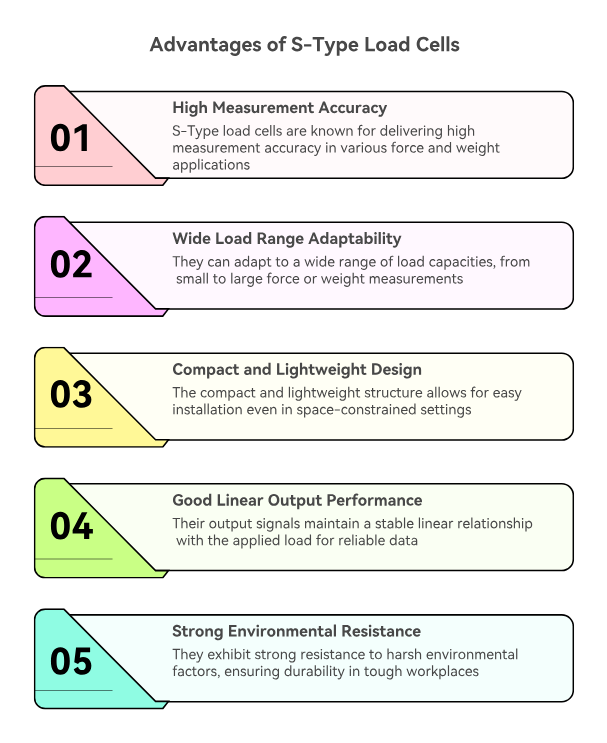

Advantages of S-Type Load Cells

S-type load cells have earned their popularity due to a unique combination of strengths that make them suitable for a wide range of applications. Here are some of their key advantages:

1. Versatility in Measuring Tension and Compression

One of the most significant benefits of S-type load cells is their ability to measure both tension (pulling forces) and compression (pushing forces) with equal accuracy. This dual functionality makes them ideal for applications where forces may act in either direction, such as in material testing machines, hoists, or cable tension monitoring systems.

2. High Accuracy and Sensitivity

The concentrated strain in the central section of the S-shape allows for precise measurement, even at low load levels. Many S-type load cells offer accuracy classes of 0.1% or better, meaning their output deviates from the true force value by less than 0.1% over their rated range. This level of precision is essential in industries like pharmaceuticals, where dosage accuracy is critical, or aerospace, where weight and balance measurements must be exact.

3. Compact Design

S-type load cells are relatively small compared to other load cell types like beam or column load cells, making them easy to integrate into tight spaces. Their compact size is particularly advantageous in automated machinery, robotics, and portable testing equipment, where space is often limited.

4. Robust Construction

Built from high-strength alloys and protected by encapsulation, S-type load cells are designed to withstand harsh industrial environments. They can operate in temperatures ranging from -40°C to 150°C (depending on the model), resist vibration and shock, and tolerate exposure to chemicals or moisture (if properly sealed). This durability ensures a long service life, even in demanding applications.

5. Cost-Effectiveness

Despite their high performance, S-type load cells are generally more affordable than specialized load cells like piezoelectric or capacitive sensors. This cost-effectiveness, combined with their versatility, makes them a popular choice for both industrial and academic applications where budget constraints may exist.

Applications of S-Type Load Cells

The versatility, accuracy, and durability of S-type load cells have led to their adoption in a diverse array of industries. Let’s explore some of the most common applications:

1. Industrial Manufacturing and Automation

In manufacturing, S-type load cells are used to monitor and control processes where force is a critical parameter. For example, in assembly lines, they may measure the torque applied when tightening bolts to ensure they are neither too loose (risking failure) nor too tight (damaging components). In plastic injection molding, load cells can detect jams by measuring abnormal forces on the mold, triggering an automatic shutdown to prevent damage. They are also used in robotic arms to provide feedback on grip strength, ensuring delicate objects are handled without being crushed or dropped.

2. Material Testing

Material testing laboratories rely heavily on S-type load cells to determine the mechanical properties of materials like metals, plastics, and composites. Tensile testing machines use S-type load cells to measure the force required to stretch a sample until it breaks, providing data on ultimate tensile strength, yield strength, and elongation. Similarly, compression testing machines use these load cells to evaluate the strength of concrete, ceramics, or packaging materials. The precision of S-type load cells ensures that test results are accurate and repeatable, which is essential for material certification and quality control.

3. Weighing and Force Measurement Systems

While platform scales often use beam load cells, S-type load cells are preferred for applications where space is limited or where both tension and compression may be encountered. For example, hanging scales (used in warehouses to weigh heavy objects suspended from cranes) use S-type load cells due to their ability to handle tension loads. They are also used in small bench scales and laboratory balances, where their high sensitivity allows for precise measurement of small weights.

4. Aerospace and Defense

In the aerospace industry, where safety and reliability are paramount, S-type load cells play a vital role in testing aircraft components, such as wings, landing gear, and engine mounts. They are used to simulate the forces experienced during flight (e.g., lift, drag, turbulence) and ensure that components can withstand extreme conditions. In defense applications, load cells may be integrated into missile guidance systems or armor testing equipment to measure impact forces and structural integrity.

5. Medical Devices

The medical field requires precise force measurement for applications ranging from surgical tools to rehabilitation equipment. S-type load cells are used in devices like robotic surgical systems to control the force applied during procedures, preventing tissue damage. They also appear in physical therapy machines, where they monitor the resistance provided to patients during exercises, ensuring workouts are safe and effective. In prosthetics, load cells can measure the pressure exerted by artificial limbs, helping to optimize fit and comfort.

6. Civil Engineering and Structural Monitoring

Bridges, buildings, and dams are subject to constant forces from traffic, wind, and water. S-type load cells are embedded in these structures (or attached to cables and supports) to monitor strain and stress over time, providing early warning of potential failures. For example, in suspension bridges, load cells measure the tension in cables to ensure they remain within safe limits, while in buildings, they may monitor the load on support beams during construction or after earthquakes.

7. Food and Pharmaceutical Processing

In the food and pharmaceutical industries, hygiene and precision are critical. S-type load cells made from stainless steel (which is easy to clean and resistant to corrosion) are used in filling machines to measure the weight of ingredients or medications, ensuring accurate dosages. They also appear in packaging equipment, where they verify that packages are filled to the correct weight, compliance with regulatory standards, and prevent product waste.

Factors to Consider When Selecting an S-Type Load Cell

Choosing the right S-type load cell for a specific application requires careful consideration of several factors. Here are the key criteria to keep in mind:

1. Load Capacity

The load cell’s rated capacity (the maximum force it can measure safely) is the first and most critical factor. Selecting a load cell with a capacity too low may result in overload and damage, while one with a capacity too high will sacrifice sensitivity, leading to inaccurate measurements for small loads. As a general rule, the expected operating load should be between 20% and 80% of the load cell’s rated capacity. This range ensures optimal sensitivity while providing a safety margin against unexpected overloads.

2. Accuracy Class

Load cells are rated by accuracy classes (e.g., 0.02, 0.05, 0.1, 0.2), which indicate the maximum allowable error over their operating range. Higher accuracy classes (lower numbers) are more precise but also more expensive. For applications like laboratory testing, where precision is critical, a class 0.05 or 0.1 load cell may be necessary. For general industrial use, a class 0.2 or 0.5 load cell may be sufficient.

3. Environmental Conditions

Consider the environment in which the load cell will operate. Factors like temperature range, humidity, exposure to chemicals, and vibration can affect performance. For outdoor or wet environments, choose a load cell with a high IP rating (e.g., IP68 for submersible applications) and corrosion-resistant materials like stainless steel. For high-temperature environments, look for load cells with temperature-compensated strain gauges and operating temperature ranges that match your needs.

4. Mounting Requirements

Proper mounting is essential for accuracy. S-type load cells can be mounted in tension (e.g., hanging from a ceiling) or compression (e.g., standing on a floor), but the mounting hardware must align the load cell axially to avoid side loads or bending. Some load cells come with integral mounting accessories (e.g., clevises, eye bolts), while others require custom mounting solutions. Ensure that the mounting surface is flat and rigid to prevent flexing, which can introduce measurement errors.

5. Output Signal Type

Load cells produce a low-level analog output (typically 2-4 mV/V, meaning 2-4 millivolts per volt of excitation voltage). This signal must be conditioned using a transmitter or amplifier to convert it into a more usable form, such as 4-20 mA, 0-10 V, or a digital signal (e.g., RS485, Modbus). Consider whether your system requires analog or digital output and choose a load cell compatible with your data acquisition or control system.

6. Material and Construction

The material of the load cell element affects durability and corrosion resistance. Stainless steel is ideal for harsh or wet environments, while aluminum is lighter and more cost-effective for dry, indoor applications with lower load capacities. Also, check for features like hermetic sealing (for moisture protection) or surge protection (to guard against electrical spikes) if needed.

Installation and Maintenance Tips

Even the best load cell will underperform if not installed and maintained properly. Here are some best practices to ensure optimal performance:

Installation Best Practices

-

Ensure Axial Alignment: Misalignment can cause bending or torsion in the load cell, leading to errors. Use alignment tools like spirit levels or laser alignment systems, and consider spherical washers or self-aligning mounts to compensate for minor misalignments.

-

Avoid Over-Tightening Mounting Hardware: Excessive torque when tightening bolts can introduce preload or deformation in the load cell, affecting accuracy. Follow the manufacturer’s recommended torque values.

-

Protect Cables: The load cell’s output cable is vulnerable to damage from abrasion, moisture, or electromagnetic interference (EMI). Route cables away from power lines and motors to minimize EMI, and use cable protectors or conduit in high-traffic areas.

-

Calibrate After Installation: Even if the load cell is calibrated at the factory, installation can introduce stresses that affect accuracy. Always calibrate the load cell after mounting using known weights or force standards.

Maintenance Tips

-

Regular Inspection: Periodically check the load cell for signs of damage, corrosion, or loose mounting hardware. Clean the load cell and mounting surfaces to remove dirt and debris, which can cause friction or interfere with strain measurement.

-

Calibration Schedule: Load cells drift over time due to factors like fatigue, temperature cycling, and material creep. Establish a regular calibration schedule (e.g., annually for industrial applications, quarterly for critical laboratory use) to ensure accuracy. Calibration should be performed by a qualified technician using traceable standards.

-

Avoid Overload: Use overload protection devices (e.g., shear pins, limit switches) to prevent accidental overload, which can permanently damage the load cell.

-

Handle with Care: Even robust load cells can be damaged by rough handling. Avoid dropping or striking the load cell, and never use it as a lifting point unless explicitly rated for that purpose.

Common Challenges and Troubleshooting

Despite their reliability, S-type load cells can encounter issues that affect performance. Here are some common problems and how to troubleshoot them:

1. Zero Drift

Zero drift occurs when the load cell’s output signal changes when no load is applied, often due to temperature fluctuations, loose mounting, or strain gauge degradation. To troubleshoot, check for loose bolts, ensure the load cell is at ambient temperature, and clean the mounting surfaces. If drift persists, the load cell may need recalibration or replacement.

2. Non-Linear Output

A non-linear output (where the signal does not increase proportionally with load) can be caused by overloading, misalignment, or damage to the strain gauges. Verify that the load is within the load cell’s capacity, check alignment, and inspect the strain gauge bonding for cracks or lifting.

3. No Output Signal

If the load cell produces no output, check the power supply (excitation voltage), cable connections, and wiring for breaks or shorts. A damaged Wheatstone bridge (e.g., a broken strain gauge wire) will also result in no output, requiring repair or replacement of the load cell.

4. Noise in the Signal

Electrical noise can manifest as fluctuations in the output signal, often caused by EMI from nearby equipment or poor grounding. Shielded cables, twisted-pair wiring, and proper grounding of the load cell and signal conditioner can reduce noise.

Conclusion

From the unassuming S-shaped metal spring to cloud-connected, self-diagnosing smart sensors, the S-type load cell has proven itself far more than a simple force transducer—it is the quiet guardian of precision across modern industry. Whether you are tightening a bolt on an EV battery line, certifying the tensile strength of aerospace alloy, or monitoring the cable tension of a 10 km suspension bridge, an S-beam delivers laboratory-grade accuracy in a package rugged enough for the harshest plant floor. Select the right capacity, protect it from misalignment and overload, and this small but mighty sensor will repay you with decades of trustworthy data—and the peace of mind that comes from knowing your process, product and people are safe.