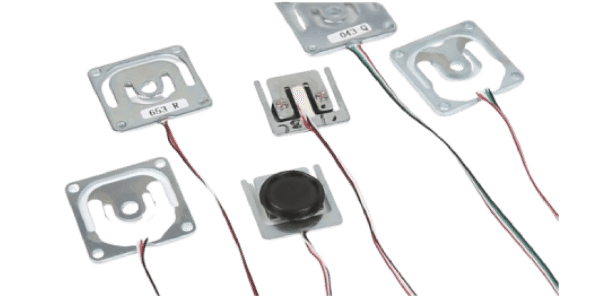

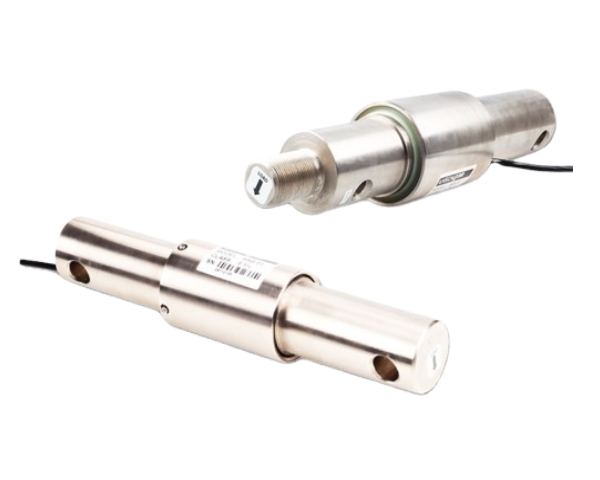

Load cells are critical components in industries ranging from manufacturing and construction to healthcare and research. These precision instruments measure force, weight, and tension with remarkable accuracy, making them indispensable for quality control, safety monitoring, and data-driven decision-making. However, like any sensitive equipment, load cells require proper care—especially when not in use. Improper storage can lead to calibration drift, physical damage, or even permanent failure, compromising their performance and increasing replacement costs.

In this blog, we’ll walk you through the step-by-step process of storing load cells correctly, covering everything from cleaning and inspection to environmental control and long-term maintenance. Whether you’re a warehouse manager, a lab technician, or a hobbyist using load cells for personal projects, these tips will help you protect your investment and ensure your load cells remain reliable for years to come.

Why Proper Storage Matters for Load Cells

Before diving into storage techniques, let’s first understand why storing load cells correctly is so important. Load cells are engineered with delicate components, including strain gauges, wiring, and housing materials, all of which are vulnerable to damage from external factors. Here are the key risks of improper storage:

-

Calibration Drift: Dust, moisture, or physical stress during storage can alter the load cell’s sensitivity, leading to inaccurate readings when it’s put back into use. Recalibrating a drifted load cell is time-consuming and costly.

-

Physical Damage: Dropping, crushing, or bending the load cell—even accidentally—can warp its structure or damage internal components. For example, a load cell with a bent beam may no longer measure force evenly.

-

Corrosion: Exposure to humidity, chemicals, or salt (in marine or industrial environments) can cause rust or corrosion on metal parts, weakening the load cell and impairing its functionality.

-

Wiring Degradation: Loose or frayed wires, often caused by improper handling during storage, can disrupt signal transmission, leading to erratic data or complete failure.

By following proper storage practices, you can mitigate these risks, extend the lifespan of your load cells, and maintain their precision.

Step 1: Clean the Load Cell Thoroughly Before Storage

The first step in storing a load cell is to clean it properly. Any dirt, debris, or residue left on the surface can attract moisture, cause corrosion, or interfere with components over time. Here’s how to do it:

For General Cleaning

-

Power Off and Disconnect: If the load cell is connected to a system, disconnect it from power sources and data cables to avoid electrical damage during cleaning.

-

Remove Loose Debris: Use a soft-bristled brush (like a clean paintbrush or makeup brush) to gently sweep away dust, dirt, or particles from the load cell’s surface, crevices, and mounting points. Avoid using compressed air, as it can force debris into sensitive areas like strain gauge connections.

-

Wipe with a Mild Cleaner: Dampen a lint-free cloth with a mild, non-abrasive cleaner (such as isopropyl alcohol or a 50-50 mix of water and vinegar). Gently wipe the load cell’s housing, avoiding direct contact with the strain gauge area (if exposed). For stubborn stains, use a soft sponge, but never scrub—excessive pressure can damage delicate components.

-

Dry Completely: After cleaning, let the load cell air-dry in a well-ventilated area. Ensure there’s no moisture left, as trapped water can lead to rust or mold.

For Specialized Environments

If the load cell was used in harsh conditions (e.g., industrial settings with oil, chemicals, or saltwater), take extra precautions:

Degrease if Necessary: Use a degreaser (like mineral spirits) to remove oil or grease, then follow with a mild cleaner to neutralize the degreaser.

Rinse with Distilled Water: For saltwater exposure, rinse the load cell with distilled water to remove salt residue, then dry thoroughly.

Step 2: Inspect for Damage or Wear

After cleaning, inspect the load cell for signs of damage that might worsen during storage. Catching issues early can prevent further harm and save you from costly repairs later. Here’s what to look for:

Visual Inspection

-

Housing and Structure: Check for cracks, dents, or bending in the load cell’s metal or plastic housing. Even small cracks can expand over time, especially if exposed to temperature fluctuations.

-

Wiring and Cables: Examine the cables for fraying, cuts, or loose connections. Look at the connectors (e.g., USB, RS485) for bent pins or corrosion. If the load cell has exposed wires, ensure they’re insulated and not touching metal parts.

-

Strain Gauges (If Visible): If the strain gauges are accessible (e.g., in some beam load cells), check for signs of damage, such as lifting, tearing, or discoloration. Strain gauges are extremely sensitive—even a small tear can render the load cell inaccurate.

Functional Testing (Optional but Recommended)

If possible, perform a quick functional test before storage to ensure the load cell is working correctly. Connect it to a readout device and apply a small, known weight to verify that readings are stable and within the expected range. If you notice inconsistent or erratic data, the load cell may need calibration or repair before storage.

Step 3: Choose the Right Storage Container

The container you use to store your load cell plays a crucial role in protecting it from physical damage, moisture, and dust. Here are the best options:

Hard-Shell Cases

For load cells that are frequently transported or stored in busy environments (e.g., warehouses, job sites), a hard-shell case with foam padding is ideal. Look for cases with:

-

Customizable Foam Inserts: These allow you to cut out a precise shape for the load cell, preventing movement during storage.

-

Waterproof or Water-Resistant Seals: To protect against moisture in humid environments.

-

Sturdy Construction: Materials like polypropylene or aluminum that can withstand impacts.

Cardboard Boxes (For Short-Term Storage)

If you’re storing the load cell for a few weeks or months and it’s in a controlled environment (e.g., a dry closet), a sturdy cardboard box lined with bubble wrap or foam can work. However, avoid cardboard in damp areas, as it absorbs moisture easily.

Anti-Static Bags (For Sensitive Electronics)

Load cells with built-in electronics (e.g., digital load cells) are sensitive to static electricity, which can damage internal circuits. Store these in anti-static bags or containers to prevent static discharge.

Pro Tip: Label the container with the load cell’s model number, serial number, and date of storage. This makes it easier to track inventory and ensures you can quickly identify the load cell when needed.

Step 4: Control the Storage Environment

The environment in which you store your load cell is just as important as the container itself. Load cells thrive in stable, dry conditions. Here’s how to optimize the storage space:

Temperature

-

Ideal Range: Most load cells should be stored at temperatures between 10°C (50°F) and 30°C (86°F). Extreme heat can warp plastic components or degrade adhesives, while freezing temperatures can cause moisture to expand and crack metal parts.

-

Avoid Fluctuations: Rapid temperature changes (e.g., storing near a heater or air conditioner) can lead to condensation, which promotes rust. Choose a storage area with consistent temperature, such as a climate-controlled room or cabinet.

Humidity

-

Keep It Dry: Aim for a relative humidity (RH) of 30–50%. High humidity (above 60%) encourages mold, rust, and corrosion, while very low humidity (below 20%) can dry out rubber gaskets or wiring insulation.

-

Use Desiccants: Place silica gel packets or calcium chloride desiccants in the storage container to absorb excess moisture. Replace desiccants every 2–3 months, or when they become saturated (silica gel turns from blue to pink when full).

Light and Airflow

-

Avoid Direct Sunlight: UV rays can fade labels, weaken plastic housing, and degrade adhesives over time. Store load cells in a dark or shaded area.

-

Ensure Ventilation: While humidity must be controlled, a well-ventilated space prevents the buildup of stale air and mold. Avoid storing load cells in sealed, airtight rooms without airflow.

Location

-

Avoid High-Traffic Areas: Store load cells away from busy walkways, machinery, or areas where they might be knocked over or stepped on.

-

Keep Away from Chemicals: Never store load cells near corrosive substances (e.g., acids, solvents) or strong odors, as these can damage materials or leave residues.

Step 5: Position the Load Cell Correctly in Storage

How you position the load cell in its container matters. Incorrect positioning can lead to stress on the load cell’s structure, especially for load cells with delicate beams or cantilevers. Follow these guidelines:

-

Avoid Weight or Pressure: Never stack heavy objects on top of the load cell, and don’t place it in a position where its sensing element (e.g., the beam) is bearing weight. For example, a single-point load cell should be stored flat, not on its side, to prevent bending.

-

Secure Moving Parts: If the load cell has moving components (e.g., a tension load cell with a hook), secure them with tape or ties to prevent them from swinging and causing damage during storage.

-

Store Cables Properly: Coil cables loosely (avoid tight kinks) and secure them with cable ties. Never wrap cables around the load cell itself, as this can create pressure points.

Step 6: Long-Term Storage Maintenance

If you plan to store a load cell for more than six months, periodic maintenance is essential to prevent degradation. Here’s what to do:

-

Inspect Every 3–6 Months: Open the storage container and check for signs of moisture, rust, or pest infestations (e.g., rodents chewing wires). Wipe the load cell with a dry cloth and replace desiccants if needed.

-

Test Calibration Annually: Even in storage, load cells can drift out of calibration. If possible, connect the load cell to a readout device once a year to verify accuracy. If readings are off, schedule a professional calibration before putting it back into use.

-

Rotate Storage Positions (For Large Load Cells): For heavy load cells stored on shelves, rotate their position every few months to prevent warping from constant pressure on one side.

Common Mistakes to Avoid

To ensure your load cell stays in top condition, steer clear of these common storage errors:

-

Leaving the Load Cell Connected to Power: Even if not in use, leaving a load cell connected to a power source can cause overheating or battery drain (for wireless models).

-

Using Harsh Cleaners: Abrasive chemicals (e.g., bleach, acetone) can damage the load cell’s housing or strain gauges. Stick to mild, non-corrosive cleaners.

-

Ignoring Small Damages: A tiny crack or frayed wire might seem insignificant, but it can worsen over time. Repair or replace damaged parts before storage.

-

Storing in Unstable Environments: Basements, garages, or outdoor sheds often have high humidity or temperature fluctuations—avoid these unless the area is climate-controlled.

Conclusion

Properly storing a load cell when not in use is a simple yet critical step in maintaining its accuracy, reliability, and lifespan. By following the steps outlined in this guide—cleaning thoroughly, inspecting for damage, choosing the right container, controlling the environment, positioning correctly, and performing regular maintenance—you can protect your investment and ensure your load cell is ready to deliver precise measurements when you need it most.

Remember, a well-stored load cell is a cost-effective load cell. By taking the time to store it properly, you’ll avoid expensive repairs, reduce downtime, and extend the life of this essential tool. Whether you’re storing a small load cell for a home project or a fleet of industrial load cells, these practices will help you get the most out of your equipment for years to come.

Have questions about load cell storage? Share your thoughts in the comments below, and we’ll help you find the best solution for your needs!