Wireless dynamometers have revolutionized force and torque measurement by eliminating cables, improving portability, and enabling data collection in hard-to-reach locations. But with various models, specs, and features on the market, selecting the right one can be challenging. This comprehensive guide breaks down the critical factors—from measurement range and wireless technology to software and durability—to help you make an informed decision and invest in the best tool for your specific needs.

1. Understanding Your Application: The First Step

Define your primary use case to narrow down your options. Wireless dynamometers are used across diverse fields:

- Manufacturing & Quality Control: Bolt torque verification, assembly line testing, press-fit force measurement.

- Maintenance & Repair: Calibration of tools, tensioning of belts/chains, troubleshooting mechanical systems.

- Research & Development: Product fatigue testing, material strength analysis, prototype validation.

- Aerospace & Automotive: Critical fastener torque auditing, clutch/brake pedal force measurement.

- Biomechanics & Ergonomics: Measuring grip strength, joint torque, or operational forces on medical devices.

Ask yourself: Will it be used in a clean lab, on a factory floor, or outdoors? Is real-time data streaming needed, or just data logging?

2. Key Specification #1: Measurement Range & Accuracy

This is the core of any dynamometer's capability.

-

Force vs. Torque: Determine if you need to measure linear force (N, lbf, kgf) or rotational torque (N·m, lb·ft, lb·in).

- Force Gauges/Dynamometers: For push/pull/tension applications.

- Torque Wrenches/Sensors: For rotational fastening and turning applications.

- Combo Units: Some sensors can measure both with different attachments.

- Capacity (Range): Choose a model where your typical measurements fall within 20%-80% of its maximum capacity for optimal accuracy. Consider having both a high-capacity and a low-capacity unit for varied tasks.

-

Accuracy & Resolution:

- Accuracy: Typically expressed as ±% of Full Scale. For critical QC, look for ≤±0.5% FS. For general use, ±1% FS may suffice.

- Resolution: The smallest detectable change in measurement. Higher resolution is key for detecting subtle variations.

- Sampling Rate: For dynamic or peak force capture (e.g., impact testing), a high sampling rate (≥1000 Hz) is essential.

3. Key Specification #2: Wireless Protocol & Range

The "wireless" aspect demands careful evaluation.

-

Standard Protocols:

- Bluetooth Classic/BR-EDR: Common, good range (up to 10m typical), compatible with many devices.

- Bluetooth Low Energy (BLE): Excellent for long battery life, but may have lower data throughput. Ideal for periodic logging.

- Proprietary Wireless (ISM Band): Some industrial models use dedicated radio for longer range (100m+) and superior interference immunity in noisy factories.

- Effective Range: Check the rated line-of-sight range. Consider obstacles like walls and machinery that will reduce it. For large facilities, a proprietary long-range system may be necessary.

- Multi-Sensor & Network Support: Can the system connect to multiple sensors simultaneously? Does it support a star or mesh network for large-scale testing setups?

- Data Logging Capability: A crucial feature. The device should store readings internally when out of range, then sync when the connection is re-established.

4. Key Specification #3: Battery Life & Charging

Nothing kills productivity like a dead battery.

-

Battery Type & Runtime:

- Rechargeable Li-ion: Standard. Look for >40 hours of continuous operation on a single charge.

- User-Replaceable vs. Internal: User-replaceable batteries or external battery packs allow for hot-swapping during extended shifts.

-

Charging Options:

- USB-C Charging: Modern and convenient.

- Docking Stations: Useful for fleet management—store, charge, and sync data automatically.

- Power-Saving Features: Auto-sleep/wake functions and adjustable data transmission intervals significantly extend battery life.

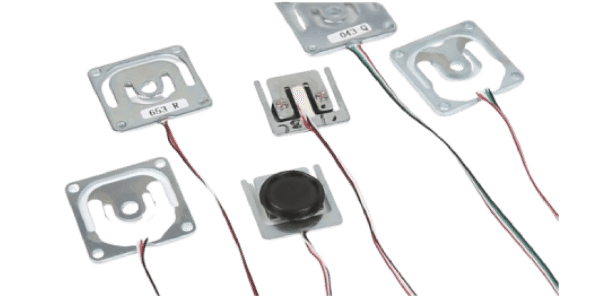

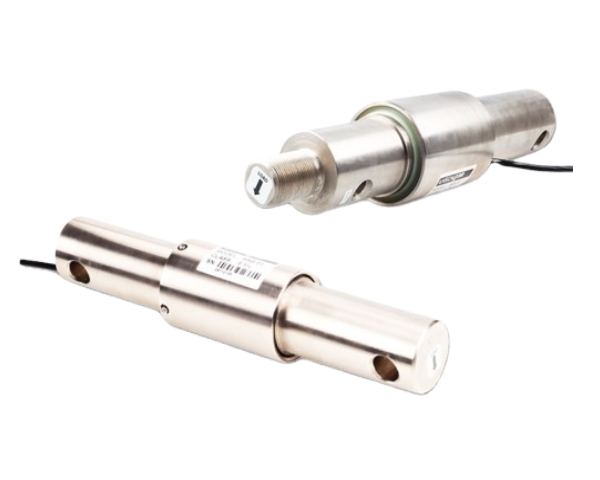

5. Key Specification #4: Physical Design & Durability

The tool must survive its environment.

-

Enclosure & IP Rating:

- IP54: Protected against dust and water splashes. Suitable for most workshops.

- IP65/IP67: Dust-tight and protected against low-pressure jets or temporary immersion. Essential for washdown areas or outdoor use.

- Construction Material: Aluminum or stainless steel housings offer the best durability for industrial settings.

- Ergonomics & Display: Is there a built-in display for local readings? Is it backlit for low-light conditions? Is the grip comfortable for prolonged use?

- Accessory Compatibility: Ensure the unit has standard threads (e.g., ¼"-28, M6, M8) or adapters for hooks, pushing rods, torque wrench squares, or custom fixtures.

6. Key Specification #5: Software & Data Management

The software transforms raw data into actionable insights.

-

Companion App/PC Software: Look for intuitive software that provides:

- Real-time graphing and visualization.

- Statistical analysis (Min, Max, Avg, Std. Dev).

- Pass/Fail judgment with programmable high/low limits.

- Customizable reporting and data export (CSV, PDF).

- API & System Integration: For automated test stands, check if the manufacturer provides an API or SDK for integration with LabVIEW, MATLAB, or custom PLC/SCADA systems.

- Cloud Connectivity: Advanced systems offer direct cloud upload for centralized data management, traceability, and team access.

7. Key Specification #6: Calibration & Compliance

Trust in your measurements is paramount.

- Traceable Calibration: The device should come with a certificate of calibration traceable to national standards (e.g., NIST, UKAS).

- Calibration Interval: Typical intervals are 12 months. Choose a supplier that offers quick, affordable recalibration services.

- Compliance & Standards: For regulated industries, ensure the instrument complies with relevant standards (e.g., ISO 6789 for torque tools, ISO 376 for force calibration).

- Warranty & Support: A minimum 2-year warranty and accessible technical support are strong indicators of product quality and manufacturer confidence.

8. Comparison Checklist & Final Recommendations

Use this checklist when evaluating models:

- Application clearly defined (Force/Torque, Environment).

- Range covers 20-80% of typical measurements.

- Accuracy (±%FS) meets your quality standards.

- Wireless protocol & range suit your workspace.

- Battery life > 40hrs; convenient charging.

- IP rating matches environmental hazards.

- Software features enable needed analysis/reporting.

- Calibration certificate included; support plan available.

Final Recommendation: There is no single "best" wireless dynamometer—only the best one for your specific requirements. Prioritize accuracy and reliability over flashy features. For mission-critical or harsh environment applications, invest in an industrial-grade instrument from a reputable manufacturer known for sensor technology.

At Galoce, we engineer precision force and torque sensors that form the heart of reliable measurement systems. Whether you're evaluating a final product or building a custom wireless testing solution, contact our engineering team to discuss how our core sensing technology can meet your demands for accuracy and durability.