In the pursuit of virtual racing realism and faster lap times, one upgrade consistently rises above the rest: the load cell brake pedal. Moving beyond traditional position-sensing pedals, load cell technology transforms braking from a guesswork of pedal travel into an intuitive, muscle-memory-driven act of pressure application. This guide explains the technical magic behind load cell pedals and why they are considered the single most important hardware upgrade for serious sim racers.

The Core Problem: Position vs. Pressure Sensing

Traditional entry-level pedals use potentiometers or hall effect sensors that measure the distance the pedal travels. Your foot position dictates the brake input. This creates a fundamental disconnect from reality:

- Inconsistent Modulation: It's difficult for your brain and muscles to consistently remember and replicate a specific pedal position under stress.

- Lack of Physical Feedback: A light spring provides minimal resistance, offering no sense of how hard you're actually pressing.

- Real Cars Don't Work That Way: In a real vehicle, the braking force is determined by the hydraulic pressure you generate in the master cylinder, not by how far the pedal moves (which is relatively small and firm).

What is a Load Cell and How Does It Work in a Pedal?

A load cell is a transducer that converts a force (load) into an electrical signal. In a sim racing brake pedal:

- Force Application: You press the pedal pad, compressing an elastomer rubber stack, a hydraulic damper, or a stiff spring.

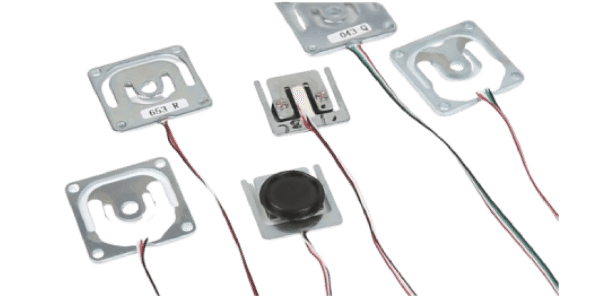

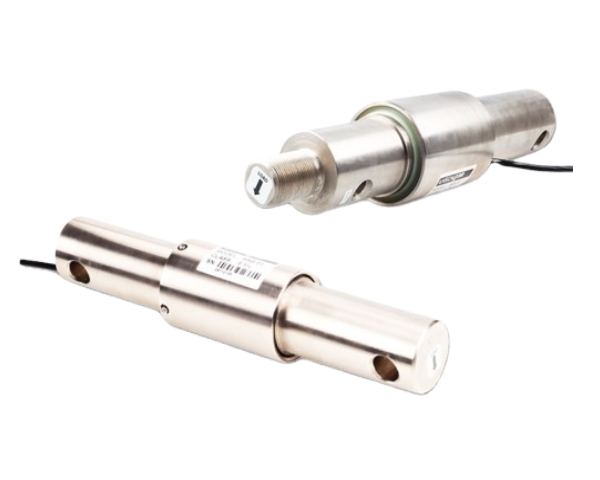

- Force Measurement: A small, durable load cell sensor, typically a strain gauge type, is positioned within the pedal assembly to measure the force/pressure you apply, not the distance traveled.

- Signal Conversion: The load cell outputs a signal proportional to the applied force. This signal is sent to the pedal controller.

- Software Calibration: The pedal software allows you to set a maximum force (e.g., 60kg), creating a linear or custom curve that maps your applied pressure to 100% brake input in the sim.

The key takeaway: Your brain learns to associate a specific leg pressure with a specific braking force, which is far more intuitive and repeatable.

The Physics of Real Braking: Mimicking a Real Car

Load cell pedals bridge the sim-to-real gap by replicating the force feedback of a real brake system.

- Progressive Resistance: As you press harder, the resistance increases non-linearly, just like a real brake pedal pushing against hydraulic pressure.

- Muscle Memory Development: Your leg muscles develop memory for force, not position. This skill is directly transferable to real-world driving.

- Improved Pedal Feel: High-end pedals use customizable elastomer stacks (rubber bushings of varying hardness) to simulate the initial "bite point" and progressive stiffness of a race car's brake system.

Key Advantages of Load Cell Brakes for Sim Racing

- Unmatched Consistency & Trail Braking: The primary benefit. You can consistently apply 70% brake pressure lap after lap, and smoothly release pressure (trail brake) by feel alone, leading to more stable corner entries.

- Faster Adaptation & Improved Lap Times: While there's a short learning curve, most drivers find they can brake later and more precisely within a few hours, often shaving seconds off their laps.

- Reduced Leg Fatigue (Long Term): While initially more physically demanding, using leg muscles statically for pressure control is less tiring than the constant micro-adjustments required for position-based pedals.

- Better Car Control Under Lock-up: Feeling a lock-up through the pressure in your foot allows for a more instinctive and rapid release and re-application of brakes.

- Customizable Feel: Adjust pre-load, max force (from 20kg to 200kg+ on pro models), and elastomer hardness to match GT, Formula, or road car preferences.

Choosing and Configuring Your Load Cell Pedal Set

Not all load cell pedals are created equal. Consider these factors:

- Maximum Force Rating: Ranges from ~50kg (entry) to 200kg (pro). 80-120kg is a popular sweet spot for most users.

- Pedal Construction: Look for all-metal construction (aluminum/steel) for durability and rigidity.

- Elastomer vs. Spring vs. Hydraulic: Elastomers offer the most realistic progressive feel. Springs are linear. Hydraulic systems aim for ultimate realism but are complex and expensive.

- Software & Calibration: Robust software for adjusting curves, dead zones, and per-pedal settings is essential.

- Mounting is Mandatory: Load cell pedals must

- Start Soft: Begin with a lower max force setting and softer elastomers. Gradually increase stiffness as your leg strength and technique improve.

Common Myths and Misconceptions

- Myth: "You need leg press strength to use them." Reality: You can set the max force to a comfortable level (e.g., 40-60kg). It's about control, not brute strength.

- Myth: "They're only for pros." Reality: They benefit drivers of all skill levels by making braking more intuitive. Even beginners develop better habits faster. Myth: "The travel doesn't matter." Reality: While force is primary, a small amount of travel (10-20mm) combined with progressive resistance is important for feel and modulation.

The Future: Load Cells in Throttle and Clutch?

While the brake pedal is the critical application, load cells are appearing in advanced throttle and clutch pedals:

- Throttle: Allows for incredibly precise modulation, beneficial for managing traction in high-power cars.

- Clutch: Can simulate the exact bite point of a real clutch through force feedback, enabling perfect starts and heel-toe downshifts. However, these are more niche and complex than load cell brakes.

For most sim racers, prioritizing a high-quality load cell brake is the most impactful first step.

Conclusion: Is the Load Cell Pedal Upgrade Worth It?

Unequivocally, yes. For any sim racer looking to improve consistency, immersion, and ultimate pace, upgrading to a load cell brake pedal is the single most effective hardware investment after a direct drive wheelbase.

It transforms braking from a visual and positional guess into a tactile, physical skill. The initial adjustment period is quickly rewarded with deeper car control, more confidence on corner entry, and lap times that reflect true driver skill rather than hardware limitations.

At Galoce, we understand the precision and durability required for high-performance sensors. The same core strain gauge technology we refine for industrial weighing is what powers the most immersive sim racing experiences. Explore our sensor technology that drives innovation from the factory floor to the virtual finish line.