In an era where the Internet of Things (IoT) is transforming industries from agriculture to manufacturing, the demand for real-time, data-driven insights has never been higher. One critical yet often overlooked component enabling this revolution is the load cell—a sensor that converts force or weight into an electrical signal. When integrated into IoT smart weighing systems, load cells become the backbone of precision, efficiency, and innovation. This blog explores how load cells empower IoT smart weighing systems, their role in various industries, key benefits, and future trends, offering a comprehensive guide for businesses looking to leverage this technology.

Understanding Load Cells: The Foundation of Smart Weighing

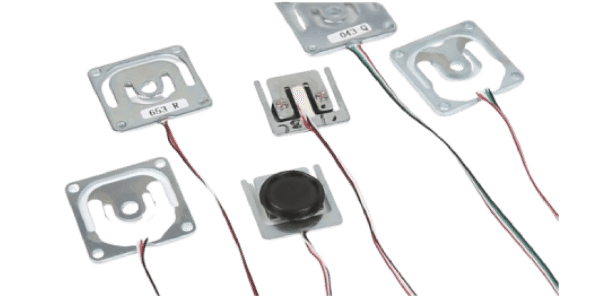

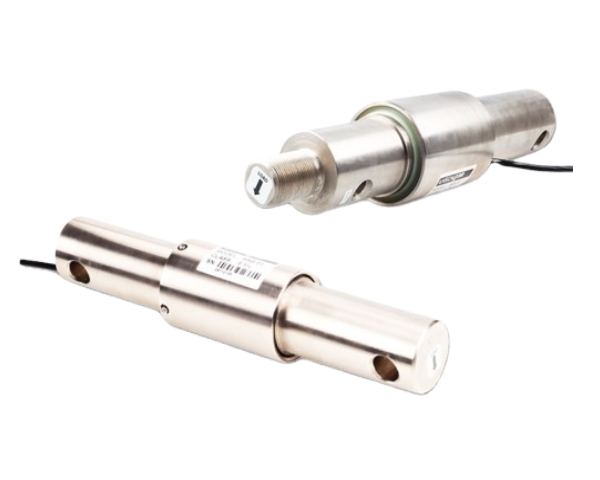

Before diving into their integration with IoT, it’s essential to grasp what load cells are and how they work. A load cell is a transducer that measures force, typically weight, by converting mechanical stress into an electrical output. Most load cells use strain gauges—thin, flexible sensors that change resistance when stretched or compressed. When a load is applied, the strain gauge deforms, altering its electrical resistance. This change is then converted into a measurable signal, which can be processed and analyzed.

Load cells come in various types, including strain gauge, hydraulic, pneumatic, and capacitive, each suited to specific applications. Strain gauge load cells are the most common due to their high accuracy, durability, and cost-effectiveness, making them ideal for IoT integration. Their ability to provide precise, real-time data is what makes them indispensable in smart weighing systems.

The Intersection of Load Cells and IoT: How They Work Together

IoT smart weighing systems combine load cells with connectivity, data processing, and cloud storage to create a seamless ecosystem. Here’s a breakdown of how these components interact:

1. Data Collection by Load Cells

At the heart of the system, load cells continuously measure weight or force. For example, in a warehouse, load cells installed under pallet racks or conveyor belts can track the weight of goods in real time. In agriculture, they might monitor the weight of grain in silos or livestock in pens. The load cell’s output—usually a small electrical signal—is sent to a nearby microcontroller or sensor hub.

2. Signal Conditioning and Processing

The raw signal from the load cell is weak and may contain noise, so it must be conditioned. Signal conditioners amplify the signal, filter out interference, and convert it into a digital format (e.g., via analog-to-digital converters). This processed data is then sent to an IoT gateway, a device that connects sensors to the cloud.

3. Connectivity via IoT Gateways

IoT gateways act as intermediaries, aggregating data from multiple load cells and transmitting it to the cloud using protocols like Wi-Fi, Bluetooth, LoRaWAN, or cellular networks (e.g., 4G/5G). This connectivity ensures that data is accessible remotely, enabling real-time monitoring from anywhere with an internet connection.

4. Cloud Storage and Analytics

Once in the cloud, the data is stored in databases and analyzed using AI and machine learning algorithms. These tools can identify patterns, predict trends, and generate actionable insights. For instance, a food processing plant might use analytics to detect inconsistencies in product weight, while a logistics company could optimize shipping routes based on real-time cargo weights.

Key Benefits of IoT Smart Weighing Systems with Load Cells

The integration of load cells into IoT smart weighing systems offers a multitude of benefits across industries. Here are the most impactful ones:

1. Real-Time Monitoring and Decision-Making

Traditional weighing systems often require manual checks, which are time-consuming and prone to human error. IoT-enabled systems with load cells provide continuous, real-time data, allowing businesses to make informed decisions instantly. For example, a manufacturing plant can monitor the weight of raw materials in production lines in real time, ensuring that batches meet quality standards and reducing waste.

2. Enhanced Accuracy and Precision

Load cells are known for their high precision, with some models offering accuracy levels as low as ±0.01% of the full-scale load. When paired with IoT analytics, this precision helps eliminate errors in inventory management, billing, and compliance. In the pharmaceutical industry, for instance, precise weight measurements are critical for ensuring medication dosages are accurate, and IoT systems with load cells can provide audit trails to meet regulatory requirements.

3. Predictive Maintenance

IoT smart weighing systems can monitor the performance of load cells and other equipment over time. By analyzing data such as load cell drift, temperature sensitivity, or signal noise, AI algorithms can predict when a load cell might fail or require calibration. This proactive approach to maintenance reduces downtime and extends the lifespan of equipment. For example, a mining company using load cells to weigh ore trucks can schedule maintenance before a sensor malfunctions, preventing costly delays.

4. Cost Savings

By automating weighing processes and reducing manual labor, IoT smart weighing systems lower operational costs. Real-time data also helps optimize resource usage—for example, a farmer can track the weight of feed in storage and order supplies only when needed, avoiding overstocking. Additionally, predictive maintenance minimizes repair costs and downtime, further boosting profitability.

5. Scalability and Flexibility

IoT systems are highly scalable, allowing businesses to add more load cells or expand to new locations without significant infrastructure changes. Whether monitoring a single scale in a retail store or thousands of sensors across a global supply chain, IoT platforms can handle large volumes of data and adapt to evolving needs.

Industry Applications: How Load Cells Drive IoT Innovation

Load cell-powered IoT smart weighing systems are transforming industries by solving unique challenges. Let’s explore some key sectors:

1. Manufacturing and Logistics

In manufacturing, load cells integrated into production lines ensure that products meet weight specifications. For example, automotive manufacturers use load cells to weigh components like engines or chassis, ensuring they are within tolerance. In logistics, load cells in warehouses and shipping containers track cargo weight, helping companies avoid overloading penalties and optimize fuel efficiency. IoT platforms can also integrate this data with inventory management systems, providing real-time stock levels and reducing the risk of stockouts.

2. Agriculture and Farming

Agriculture benefits greatly from IoT smart weighing systems. Farmers use load cells to monitor the weight of grain in silos, track livestock weight gain, and measure the amount of fertilizer or feed used. For instance, a dairy farm might use load cells under cow stalls to monitor milk production, while a grain elevator could use IoT-connected load cells to track incoming and outgoing grain, streamlining supply chain management. This data helps farmers make data-driven decisions about feeding, harvesting, and resource allocation.

3. Healthcare and Pharmaceuticals

In healthcare, precision is paramount. Load cells are used in medical devices such as patient scales, infusion pumps, and drug formulation equipment. IoT integration allows healthcare providers to monitor patient weights remotely (e.g., in home care settings) and ensure that medication dosages are accurate. Pharmaceutical companies use load cells in production to measure active ingredients, with IoT systems providing real-time data to comply with strict regulatory standards like the FDA’s Current Good Manufacturing Practice (CGMP).

4. Retail and E-Commerce

Retailers use smart weighing systems at checkout counters and in inventory management. For example, grocery stores with self-checkout kiosks use load cells to verify the weight of produce, preventing theft and ensuring accurate pricing. E-commerce warehouses use load cells in shipping stations to weigh packages, automatically calculating shipping costs and ensuring compliance with carrier weight limits. IoT integration allows retailers to track inventory levels in real time, reducing overstocking and improving customer satisfaction.

5. Waste Management

Waste management companies are increasingly using IoT smart weighing systems to optimize collection routes and billing. Load cells installed in garbage trucks measure the weight of waste collected from each location, allowing companies to charge customers based on actual usage (pay-as-you-throw models). This data also helps identify areas with high waste generation, enabling targeted recycling campaigns and reducing operational costs.

SEO Best Practices for IoT Smart Weighing Systems

To ensure this blog reaches its target audience—businesses, engineers, and decision-makers interested in IoT and smart weighing—it’s essential to incorporate SEO best practices. Here’s how:

1. Keyword Research

Identify relevant keywords such as “IoT smart weighing systems,” “load cell applications in IoT,” “real-time weight monitoring IoT,” and “predictive maintenance for load cells.” These keywords should be naturally integrated into headings, subheadings, and body text to improve search engine rankings.

2. High-Quality, Informative Content

Search engines prioritize content that provides value to readers. By explaining complex concepts like load cell technology and IoT integration in simple terms, this blog caters to both technical and non-technical audiences. Including real-world examples and case studies also enhances credibility and engagement.

3. Internal and External Linking

Linking to reputable sources (e.g., industry reports, manufacturer websites) and internal pages (e.g., related blogs on IoT sensors) improves SEO. For example, linking to a case study on a manufacturing company using IoT weighing systems adds depth and authority.

4. Mobile Optimization

With most users accessing content on mobile devices, ensuring the blog is mobile-friendly is crucial. This includes responsive design, fast loading times, and easy-to-read formatting (short paragraphs, bullet points, and subheadings).

5. Meta Descriptions and Title Tags

A compelling meta description (150–160 characters) and title tag (under 60 characters) can increase click-through rates. For example, a title tag like “How Load Cells Power IoT Smart Weighing Systems | Benefits & Applications” and a meta description summarizing the blog’s key points will attract searchers.

Future Trends: What’s Next for Load Cells and IoT

As IoT technology advances, load cells are poised to become even more integral to smart weighing systems. Here are some emerging trends to watch:

1. Miniaturization and Wireless Connectivity

Manufacturers are developing smaller, more compact load cells with built-in wireless connectivity (e.g., Bluetooth Low Energy or Zigbee). This makes installation easier, especially in tight spaces, and reduces the need for complex wiring.

2. AI-Driven Predictive Analytics

AI algorithms will become more sophisticated, enabling load cells to not only measure weight but also predict future trends. For example, in agriculture, AI could analyze historical weight data of livestock to predict growth rates and optimize feeding schedules.

3. Edge Computing

Edge computing—processing data locally on IoT devices rather than in the cloud—will reduce latency and improve real-time responsiveness. Load cells with edge computing capabilities can make instant decisions, such as triggering an alert if a weight exceeds a threshold, without waiting for cloud processing.

4. Integration with Blockchain

Blockchain technology could enhance the security and transparency of weight data. For instance, in supply chain management, blockchain can create immutable records of weight measurements, preventing fraud and ensuring compliance with regulations.

5. Sustainability

Load cells will play a role in sustainability efforts by enabling more efficient resource usage. For example, smart waste management systems with load cells can reduce carbon emissions by optimizing collection routes, while agricultural applications can minimize water and fertilizer waste.

Conclusion

Load cells are the unsung heroes of IoT smart weighing systems, providing the precision and reliability needed to drive data-driven decision-making across industries. By integrating load cells with IoT technology, businesses can achieve real-time monitoring, enhanced accuracy, predictive maintenance, and cost savings. From manufacturing to healthcare, the applications are vast and growing, with future trends like miniaturization, AI analytics, and edge computing set to further revolutionize the field.

As more industries recognize the value of IoT smart weighing systems, load cells will continue to empower innovation, efficiency, and sustainability. Whether you’re a small business looking to optimize inventory or a large corporation streamlining global supply chains, investing in load cell technology is a step toward a smarter, more connected future.

By understanding the role of load cells in IoT and leveraging SEO best practices, businesses can position themselves as leaders in this rapidly evolving space, driving growth and staying ahead of the competition. The future of smart weighing is here—and load cells are leading the way.