In the world of precision force and weight measurement, selecting the right load cell is critical for accuracy, reliability, and longevity. Among the various designs available, the spoke type load cell stands out for its unique structure and robust performance. This guide dives deep into what makes spoke type load cells special, their key benefits, and where they are most effectively used across industries.

What is a Spoke Type Load Cell?

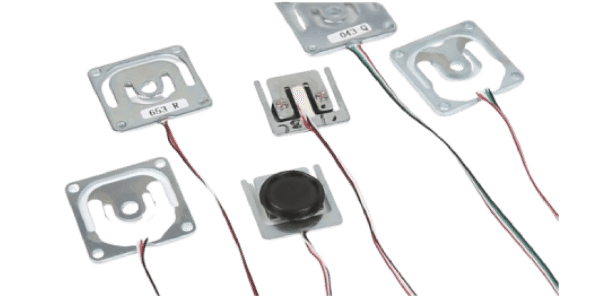

A spoke type load cell, also known as a wheel spoke sensor or low profile shear beam, is a strain gauge-based sensor designed to measure tension and compression forces. Its namesake comes from its distinctive mechanical structure, which resembles the spokes of a wheel. This design typically features a central hub connected to an outer ring through several precision-machined, elastic "spokes." When force is applied, these spokes undergo controlled deformation, and the attached strain gauges convert this mechanical strain into an electrical signal proportional to the load.

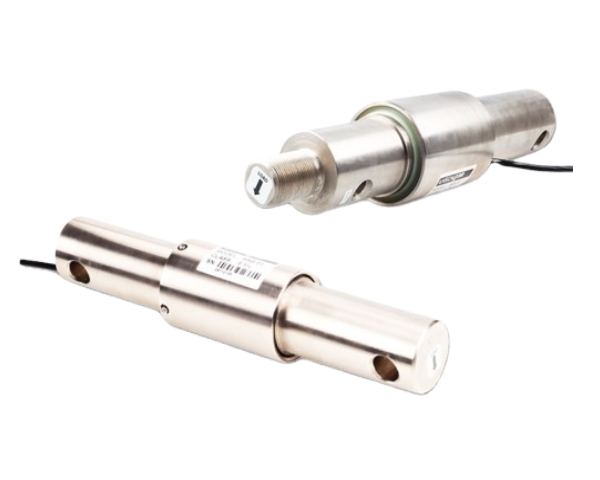

Engineered for high performance in challenging environments, these load cells are renowned for their durability and resistance to off-axis loads.

Key Features and Design Principles

The effectiveness of a spoke type load cell stems from its intelligent engineering. Here are its core features:

- Robust, Low-Profile Design: Their compact and sturdy construction allows for easy integration into space-constrained applications without sacrificing strength.

- Excellent Off-Center Load Compensation: The symmetrical spoke arrangement minimizes errors caused by loads that are not applied perfectly centrally, ensuring consistent accuracy.

- High Stiffness and Natural Frequency: They offer rapid response times and are less susceptible to vibration-induced errors, making them suitable for dynamic weighing.

- Hermetically Sealed Options: Many models are available with IP67/IP68 ratings, providing robust protection against dust, moisture, and corrosive agents for harsh industrial or washdown environments.

- Material Variety: Commonly constructed from alloy steel or stainless steel, offering choices for different capacity ranges and environmental conditions.

Advantages Over Other Load Cell Types

Why choose a spoke type load cell? Here’s a comparative look at its benefits:

- Superior Side Load Resistance: Compared to traditional bending beam cells, the spoke design inherently handles parasitic side forces much better, reducing measurement errors and mechanical wear.

- Compact & Space-Saving: Their low height profile is ideal for platform scales, onboard weighing, and applications where vertical space is limited.

- High Accuracy and Long-Term Stability: The shear force measurement principle and robust construction contribute to reliable, repeatable measurements over extended periods.

- Versatile Mounting: They can be easily installed in both tension and compression modes, offering great flexibility in system design.

- Cost-Effectiveness for Mid to High Capacities: For applications requiring capacities from 1t to 50t, they often provide an optimal balance of performance and cost.

Common Industrial Applications

Spoke type load cells are versatile workhorses found in numerous sectors:

- Truck and Platform Weighing Systems: The go-to choice for axle scales, weighbridges, and low-profile platform scales due to their durability and off-center load capability.

- Industrial Process Weighing: Used in silo, hopper, and tank weighing for inventory control and batching processes.

- On-Board Vehicle Weighing: Installed in dump trucks, forklifts, and cranes to monitor load weight in real-time, preventing overload and improving safety.

- Force Measurement in Manufacturing: Employed in press machines, roll force monitoring, and assembly line testing to ensure quality control.

- Marine and Offshore Applications: Their sealed designs make them suitable for mooring tension monitoring and deck load monitoring.

- Agricultural Equipment: Integrated into harvesters and grain carts for yield monitoring and load management.

Selection and Installation Tips

To maximize the performance of your spoke type load cell, consider these guidelines:

- Capacity Selection: Choose a rated capacity slightly above your maximum expected load (e.g., 120-150%) to include a safety margin and avoid overloading.

- Environmental Protection: Select the appropriate IP rating (e.g., IP67/IP68) and material (stainless steel for corrosive settings) based on your operating environment.

- Proper Mounting Surfaces: Ensure mounting surfaces are flat, level, and sufficiently rigid to prevent distortion that can affect accuracy.

- Use Load Cell Accessories: Incorporate high-quality mounting hardware (load buttons, plates) and consider using summing boxes or junction boxes for multi-cell systems to ensure stable signal output.

- Regular Calibration and Maintenance: Periodically calibrate the system and check for physical damage, loose connections, or buildup of debris.

Conclusion

The spoke type load cell is a premier solution for demanding force and weighing applications that require a compact sensor with exceptional resistance to side forces and harsh conditions. Its unique blend of robust construction, high accuracy, and application versatility makes it an indispensable component in modern industrial weighing systems, vehicle onboard scales, and process control. By understanding its features and following best practices for selection and installation, engineers and system integrators can achieve reliable, long-term measurement performance.

At Galoce, we offer a comprehensive range of high-quality spoke type load cells and expert technical support to help you find the perfect sensor for your specific challenge. Contact our team today to discuss your application needs.