Modern vending machines have evolved far beyond simple coin-operated dispensers. At the heart of this transformation is load cell technology—precision weight sensors that enable real-time inventory tracking, prevent stockouts, and create a smarter, more reliable customer experience. This guide explores how these sophisticated sensors work and why they're becoming essential for profitable vending operations.

The Evolution of Vending: From Mechanical to Smart Systems

Traditional vending machines relied on mechanical switches or simple infrared sensors to detect when a product was dispensed. While functional, these systems had significant limitations—they couldn't detect product jams, track partial consumption, or provide accurate real-time inventory data. The integration of load cells (strain gauge weight sensors) has transformed vending machines into intelligent retail endpoints capable of precise inventory control and data-driven decision making.

How Load Cells Work in Vending Machines

In smart vending systems, load cells are strategically installed beneath product trays, shelves, or individual compartments. Here's how they create a smart inventory system:

- Continuous Weight Monitoring: Each shelf or product row is equipped with one or more load cells that constantly measure the weight of products.

- Baseline Calibration: The system is programmed with the weight of each individual product (e.g., a 50g snack bag or a 500ml bottle).

- Real-Time Subtraction: When a product is purchased and removed, the load cell detects the weight decrease and deducts one unit from the inventory count.

- Multi-Product Shelves: Advanced algorithms can distinguish between different products on the same shelf by their unique weights, enabling mixed inventory tracking.

- Data Transmission: Inventory data is sent via IoT connectivity (cellular, Wi-Fi, Bluetooth) to a central management platform.

Key Benefits for Inventory Management

The implementation of load cell technology delivers transformative advantages for vending operators:

- Real-Time Stock Visibility: Operators know exactly how many items remain in every machine, eliminating guesswork and enabling proactive restocking.

- Elimination of Stockouts: Automatic alerts notify operators when products reach minimum thresholds, ensuring popular items are always available to customers.

- Sales Data Accuracy: Weight-based tracking provides 100% accurate sales data, crucial for financial reporting and demand forecasting.

- Theft and Malfunction Detection: Unexpected weight changes can indicate attempted theft, product jams, or vandalism, triggering immediate alerts.

- Optimized Restocking Routes: Route planners can prioritize machines with the greatest need, reducing fuel costs and improving operational efficiency.

- Reduced Shrinkage: Precise tracking minimizes losses from unrecorded sales or inventory discrepancies.

Real-World Applications & Use Cases

Load cell-equipped vending machines are revolutionizing various sectors:

- Fresh Food Vending: For perishable items like salads, sandwiches, and yogurt where stock rotation is critical and expiration dates matter.

- Electronics & High-Value Items: For headphones, phone chargers, or portable batteries where security and accurate inventory are paramount.

- Pharmaceutical Vending: In hospitals and clinics for OTC medications and medical supplies, requiring strict inventory control.

- Bulk Snack & Candy Machines: Where customers can dispense varying quantities, with billing based on precise weight measurements.

- Office Coffee & Pantry Service: Tracking consumption of coffee pods, snacks, and drinks to automate restocking and billing.

- Cashless Micro-Markets: Larger glass-front coolers where customers open the door, pick multiple items, and are charged automatically via weight sensing upon door closure.

Technical Considerations for Implementation

Successfully integrating load cells into vending machines requires careful planning:

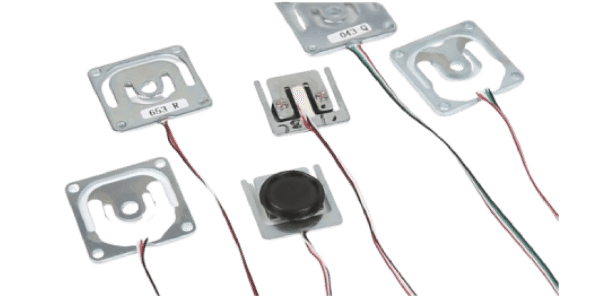

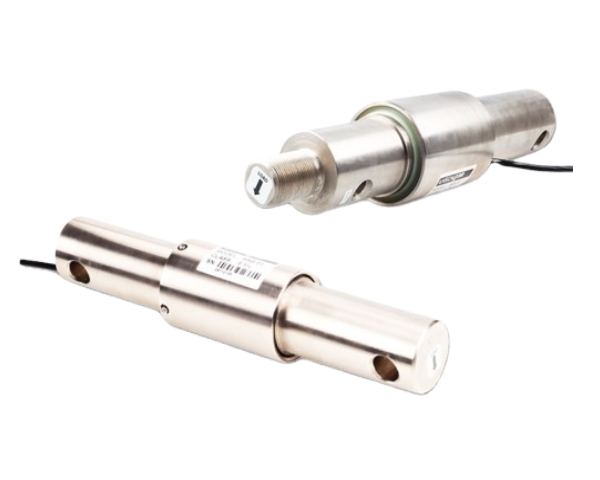

- Sensor Selection: Choosing appropriate load cell types—typically low-profile single-point load cells or shear beam load cells with capacities ranging from 1kg to 20kg per shelf.

- Environmental Factors: Sensors must withstand temperature fluctuations, vibrations from compressors, and potential moisture exposure in refrigerated units.

- Calibration & Maintenance: Regular calibration is essential to maintain accuracy, especially after machine relocation or mechanical service.

- Power Management: Efficient power design to ensure continuous weight monitoring without excessive battery drain in standalone units.

- Data Integration: Seamless connection between the load cell controller and the machine's payment system and telemetry module.

Future Trends: IoT Integration & Predictive Analytics

The future of vending lies in fully connected, intelligent systems where load cells serve as foundational data sources:

- Predictive Restocking: AI algorithms analyze historical sales patterns, seasonality, and even local event schedules to predict demand and suggest optimal stocking levels.

- Dynamic Pricing: Machines could adjust prices based on near-expiration dates (for fresh food) or time of day to maximize sales and reduce waste.

- Integration with Supply Chain: Inventory data automatically triggers orders with distributors or central warehouses, creating a seamless supply chain.

- Enhanced Customer Experience: Mobile apps could show real-time product availability before customers approach the machine.

- Multi-Sensor Fusion: Combining weight data with other sensors (like image recognition) for even greater accuracy in mixed-product shelves.

Conclusion

Load cell technology has transformed vending machines from simple dispensing devices into sophisticated retail management platforms. By providing accurate, real-time inventory data, these sensors enable operators to reduce costs, increase sales, eliminate stockouts, and deliver superior customer service. As IoT connectivity and data analytics continue to advance, the role of weight sensors will only become more central to the vending industry's evolution.

For vending machine manufacturers and operators looking to upgrade their systems, implementing reliable load cell technology is no longer an option—it's a competitive necessity. At Galoce, we provide precision load cells specifically designed for the unique demands of vending applications. Contact us to learn how our sensors can help you build smarter, more profitable vending solutions.