Load cells are integrated into nearly every type of construction machinery, enhancing safety, accuracy, and productivity. Let’s explore their role in specific machines and how they contribute to project success:

1. Cranes: Preventing Overloads and Ensuring Safe Lifting

Cranes are among the most critical pieces of construction equipment, and their safe operation depends on load cells. Tower cranes, mobile cranes, and overhead cranes all use tension load cells mounted on their hooks or cables. These load cells continuously measure the weight of the load being lifted, sending data to a display in the operator’s cabin. If the load exceeds the crane’s rated capacity, an alarm sounds, and the crane may automatically shut down to prevent tipping or structural failure.

For example, when lifting a 20-ton steel beam with a crane rated for 25 tons, the load cell ensures the operator knows the exact weight, avoiding accidental overloading. In high-rise construction, tower cranes often use load cells to monitor both the main load and the counterweight, ensuring the crane remains balanced. This data is also shared with project managers via telematics systems, allowing them to track lifting operations and optimize schedules.

2. Excavators and Backhoes: Optimizing Material Handling

Excavators and backhoes rely on compression load cells in their buckets to measure the weight of materials (e.g., soil, rock, concrete) during digging and loading. This data helps operators:

-

Avoid overloading trucks: By knowing the bucket’s weight, operators can load trucks to their maximum capacity without exceeding legal limits, reducing the number of trips required.

-

Ensure precise material quantities: In road construction, for instance, excavators use load cells to measure the amount of gravel added to asphalt mixers, ensuring the mix meets strength specifications.

-

Prevent equipment damage: Overloading an excavator’s arm can strain hydraulic systems and cause premature wear. Load cells alert operators when the bucket is too heavy, preventing costly repairs.

Some advanced excavators even use load cell data to automate tasks. For example, when loading a truck, the machine can “learn” the optimal bucket position and weight, repeating the process with minimal operator input—saving time and reducing fatigue.

3. Bulldozers and Graders: Controlling Earthmoving Operations

Bulldozers use compression load cells in their blades to measure the load of soil, sand, or snow being pushed. This information helps operators:

-

Maintain consistent grading: In site preparation, graders use load cells to ensure the ground is leveled to the required slope, reducing the need for manual surveys.

-

Optimize fuel efficiency: By knowing the blade’s load, operators can adjust engine power to match the task, avoiding unnecessary fuel consumption.

-

Prevent blade damage: Overloading the blade can bend or crack it, leading to downtime. Load cells alert operators to excessive forces, allowing them to adjust their approach.

In mining and large-scale earthmoving projects, bulldozers with load cells are often connected to GPS systems, creating 3D maps of the work area. This integration helps managers track progress and ensure the project stays on schedule.

4. Concrete Mixers and Batching Plants: Ensuring Mix Quality

Concrete is the backbone of construction, and its strength depends on precise ingredient ratios. Load cells play a vital role in concrete mixers and batching plants by measuring the weight of aggregate (sand, gravel), cement, water, and additives.

In batching plants, compression load cells are installed under storage silos and weigh hoppers. As materials are added to the mixer, the load cells ensure each ingredient is measured to the gram, preventing errors that could weaken the concrete. For example, too much water can reduce strength, while too little can make the mix unworkable. Load cell data is also logged for quality control, allowing inspectors to verify compliance with building codes.

Mobile concrete mixers (trucks) use load cells to monitor the mix during transit. If the load shifts or water is added on-site, the load cell adjusts the mix ratio, ensuring the concrete remains viable for pouring.

5. Pile Drivers: Ensuring Structural Integrity

Pile drivers are used to drive foundation piles into the ground, providing support for buildings, bridges, and other structures. Multi-axis load cells are used here to measure the impact force and penetration depth of each pile. This data helps engineers:

Verify pile capacity: The force required to drive a pile indicates its bearing capacity. If the pile resists driving more than expected, it may be hitting bedrock, requiring adjustments to the foundation design.

Prevent pile damage: Excessive force can crack or bend piles, compromising their strength. Load cells alert operators to abnormal resistance, allowing them to reduce impact energy.

Ensure uniformity: In projects with hundreds of piles, load cells ensure each one is driven to the same depth and force, maintaining consistent foundation support.

Benefits of Load Cells in Construction Machinery

The integration of load cells into construction machinery offers numerous benefits, from safety and cost savings to improved project outcomes. Below are the key advantages:

1. Enhanced Safety

Safety is the top priority in construction, and load cells are instrumental in preventing accidents. By providing real-time load data, they reduce the risk of:

Machine overloads: Cranes, excavators, and other machinery are less likely to tip, collapse, or suffer structural damage.

Worker injuries: Accidents caused by falling loads or machinery failure are minimized, protecting operators and ground crews.

Legal liabilities: Compliance with safety regulations (e.g., OSHA standards in the U.S.) reduces the risk of fines and lawsuits for construction companies.

For example, a 2020 study by the Construction Industry Institute found that projects using load cell-equipped cranes had 30% fewer lifting-related accidents compared to those without. This not only saves lives but also reduces project delays caused by investigations and downtime.

2. Increased Productivity

Load cells streamline operations by providing accurate data that optimizes workflows. For instance:

Faster loading/unloading: Excavators and bulldozers with load cells can load trucks to their maximum capacity in fewer trips, reducing transportation time.

Reduced rework: Precise material measurements (e.g., in concrete mixing) eliminate the need to redo work due to incorrect ratios, saving time and materials.

Automation: Advanced machinery uses load cell data to automate repetitive tasks (e.g., excavator bucket loading), allowing operators to focus on more complex work.

A case study by a leading construction equipment manufacturer found that load cell-equipped backhoes increased productivity by 15% on average, as operators spent less time estimating load weights and more time working.

3. Cost Savings

Load cells help construction companies save money in several ways:

-

Reduced fuel consumption: By optimizing engine power based on load data, machinery uses less fuel. For example, a bulldozer with a load cell can adjust its speed when pushing light vs. heavy loads, cutting fuel costs by up to 10%.

-

Lower maintenance costs: Preventing overloads reduces wear and tear on hydraulic systems, engines, and structural components, extending machinery lifespan and reducing repair bills.

-

Material efficiency: Accurate load measurements in concrete mixers and excavators minimize waste, lowering material costs. A small concrete batch plant, for instance, can save $50,000+ annually by reducing aggregate overuse.

4. Improved Project Management

Load cell data is often integrated with telematics and construction management software, providing project managers with real-time insights into machinery performance. This allows them to:

Track progress: Monitor how much material has been moved, lifted, or mixed, ensuring the project stays on schedule.

Optimize resource allocation: Identify underused machinery and reassign it to other tasks, reducing idle time.

Predict maintenance needs: Analyze load cell data to detect abnormal wear patterns (e.g., a crane hook with increasing resistance), allowing for proactive repairs.

For example, a project manager overseeing a highway construction site can use load cell data from excavators to track daily gravel production, adjusting schedules if targets are not met. This level of visibility is critical for large-scale projects with tight deadlines.

Challenges and Limitations

While load cells offer significant benefits, they are not without challenges. Construction companies must address these issues to maximize their effectiveness:

1. Environmental Factors

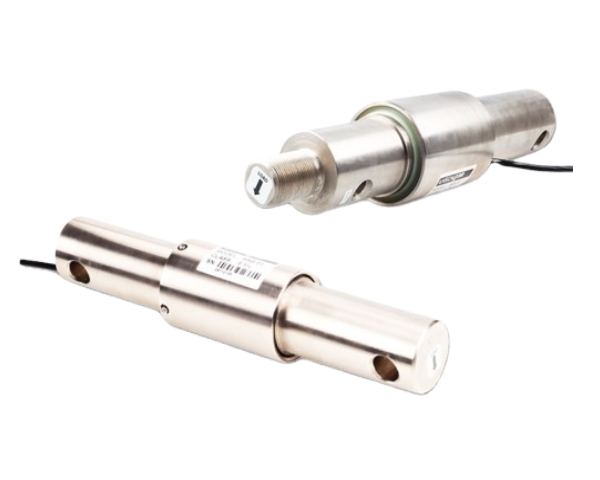

Construction sites are harsh environments, and load cells must withstand:

Extreme temperatures: Freezing cold in winter or scorching heat in summer can affect load cell accuracy.

Moisture and corrosion: Rain, snow, and chemicals (e.g., concrete additives) can damage load cell electronics.

Vibrations and impacts: Heavy machinery vibrations or sudden jolts (e.g., a pile driver’s impact) can cause sensor drift or physical damage.

To mitigate these issues, manufacturers use rugged materials (e.g., stainless steel, IP68-rated enclosures) and protective coatings. Regular calibration is also essential to ensure accuracy, as environmental factors can shift load cell readings over time.

2. Calibration and Maintenance

Load cells require regular calibration to maintain accuracy. Over time, strain gauges can drift, and mechanical components can wear, leading to incorrect readings. Calibration involves applying known weights to the load cell and adjusting the output signal to match. This process can be time-consuming and requires specialized equipment, which may be costly for small construction companies.

Additionally, load cells must be inspected for damage (e.g., cracks in the body, loose wiring) during routine maintenance. Ignoring maintenance can lead to inaccurate data, putting safety at risk.

3. Cost of Integration

While load cells save money in the long run, initial installation costs can be high, especially for retrofitting older machinery. For example, adding load cells to a fleet of 10 cranes may cost $50,000–$100,000, depending on the type and complexity of the system. Smaller companies may struggle to justify this expense, even though the ROI is typically positive within 1–2 years.

4. Operator Training

Load cell data is only useful if operators understand how to interpret it. Without proper training, operators may ignore alarms, misread displays, or fail to adjust their behavior based on load cell feedback. Construction companies must invest in training programs to ensure operators use load cell data effectively, maximizing safety and productivity.

Future Trends: The Next Generation of Load Cells

As construction technology advances, load cells are evolving to meet new demands. Here are the key trends shaping their future:

1. IoT and Connectivity

Load cells are increasingly being integrated with the Internet of Things (IoT), allowing real-time data to be shared across project teams, contractors, and equipment manufacturers. For example, a crane’s load cell data can be transmitted to a cloud-based platform, where AI algorithms analyze it to predict maintenance needs or optimize lifting schedules. This connectivity also enables remote monitoring, allowing managers to oversee operations from off-site locations.

2. Wireless Load Cells

Traditional load cells require wired connections to transmit data, which can be cumbersome in large machinery. Wireless load cells, using Bluetooth or LoRaWAN technology, eliminate this problem, making installation easier and reducing the risk of cable damage. They are particularly useful for retrofitting older equipment, where wiring would be costly or impractical.

3. Self-Calibrating Load Cells

Self-calibrating load cells use built-in sensors to detect environmental changes (e.g., temperature, vibration) and automatically adjust their readings. This reduces the need for manual calibration, saving time and ensuring accuracy in dynamic conditions. For example, a self-calibrating load cell in a concrete mixer would adjust for temperature changes that affect the mix’s weight.

4. AI-Powered Predictive Analytics

By combining load cell data with AI, construction companies can predict equipment failures before they occur. For instance, AI algorithms can analyze load patterns in a crane’s hook to detect signs of fatigue (e.g., increasing resistance during lifts), alerting managers to replace the hook before it fails. This predictive maintenance reduces downtime and extends machinery lifespan.

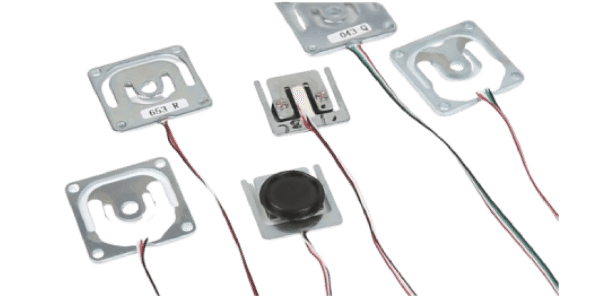

5. Miniaturization

Advancements in materials science are leading to smaller, more powerful load cells. These compact sensors can be integrated into tighter spaces (e.g., hydraulic hoses, small excavator arms) without compromising performance. Miniaturization also reduces weight, improving machinery fuel efficiency.

Conclusion

Load cells may be small in size, but their impact on construction machinery is enormous. They are the silent guardians of safety, ensuring that cranes lift within limits, excavators load accurately, and concrete mixers produce high-quality material. By providing real-time data, load cells enhance productivity, reduce costs, and empower project managers to make data-driven decisions.

The next time you see a crane lifting a steel beam or an excavator loading a truck, remember the load cell working behind the scenes. It’s not just a sensor; it’s a critical tool.

As construction continues to embrace digital transformation, load cells will play an even greater role, integrating with IoT, AI, and automation to create smarter, safer, and more efficient job sites. While challenges like environmental durability and initial costs remain, the benefits—fewer accidents, faster projects, and lower expenses—make load cells an investment worth making.

HOT keyword: