Selecting the correct load cell is critical for accuracy, safety, and longevity of your weighing system. Choose a capacity too small, and you'll overload the sensor; choose one too large, and you sacrifice precision. This step-by-step guide walks you through calculating the perfect load cell capacity, determining the right physical dimensions, and meeting region-specific requirements—whether you're building a conveyor scale in Chicago, a silo system in Germany, or a truck scale in Australia.

Why Load Cell Selection Matters

A load cell is the heart of any weighing application. An undersized load cell risks catastrophic failure and safety hazards. An oversized load cell results in poor resolution and inaccurate readings, especially in the lower range of measurement. Understanding how to calculate load cell capacity ensures optimal performance and extends equipment life by 5-10 years.

Key factors affecting selection include: maximum working load, dynamic forces, environmental conditions, installation space constraints, and regional certification requirements (NTEP for USA, OIML for Europe, CCC for China).

Step 1: Calculate Your Maximum Working Load

Start by determining the maximum weight your system will measure. This isn't just the product weight—you must include:

- Net Product Weight: The actual material being weighed (e.g., 500kg of fertilizer)

- Tare Weight: Container, hopper, or platform weight (e.g., 150kg hopper)

- Dynamic Load Factor: Impact forces during loading (typically adds 20-50%)

Basic Capacity Formula

Minimum Load Cell Capacity = (Net Weight + Tare Weight) × Dynamic Factor × Safety Factor

Example: For a 1000kg tank with 200kg hopper, moderate impact (1.3 factor), and 1.5 safety factor:

(1000 + 200) × 1.3 × 1.5 = 2,340kg → Select a 2,500kg or 3,000kg load cell

Understanding Safety Factors by Application

- Static Weighing (laboratory): 1.2-1.5x

- Standard Industrial: 1.5-2.0x

- Heavy Vibration/Mining: 2.0-3.0x

- Lift/Overload Protection Critical: 3.0-5.0x

Step 2: Choose the Right Load Cell Type by Capacity

Different load cell designs suit different capacity ranges:

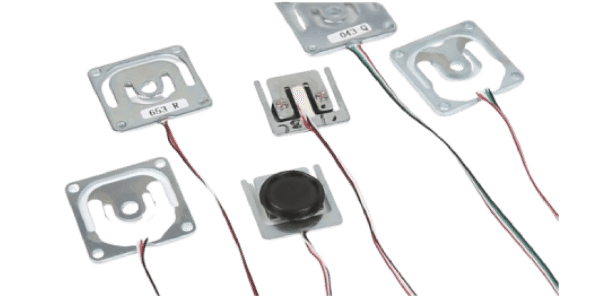

Low Capacity (0.1kg - 50kg)

Types: Single point, bending beam

Applications: Packaging machines, laboratory balances, retail scales

Geo-considerations: In Japan and South Korea, compact single-point cells dominate electronics manufacturing. European pharmaceutical labs often require IP65+ protection for washdown.

Medium Capacity (50kg - 5,000kg)

Types: Shear beam, S-type, double-ended shear beam

Applications: Pallet scales, tank weighing, conveyor belts

Geo-considerations: In the US agricultural sector (Midwest), shear beam cells for grain hoppers must handle -30°C winters. Australian mining operations require 300% overload protection for truck loading.

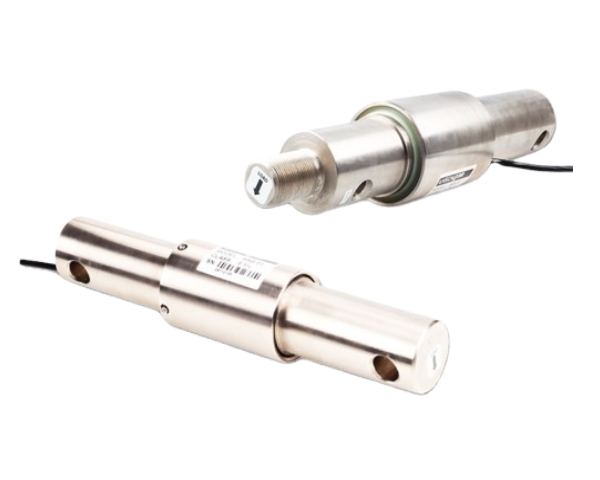

Heavy Capacity (5,000kg - 100,000kg+)

Types: Compression canister, ring torsion, digital load cells

Applications: Truck scales, rail weighbridges, silo weighing

Geo-considerations: Middle Eastern steel mills require high-temperature variants (120°C+) for molten material handling. Nordic countries need -40°C rated cells for outdoor lumber scales.

Step 3: Determine Physical Size and Mounting Constraints

Load cell dimensions must fit your mechanical structure without compromising strength.

Critical Dimensions to Measure

1. Overall Length/Width: Must fit within platform or tank foot

2. Mounting Hole Pattern: Bolt circle diameter and thread size

3. Height: Critical for portable scales and height-restricted installations

4. Cable Entry: Side entry vs. bottom entry affects waterproofing

Installation Geometry

- Compression Applications: Ensure plumbness (vertical alignment) within 2-3 degrees. Common in concrete batch plants across Southeast Asia.

- Tension Applications: RequireAlignment kits to prevent side loads. Standard for crane scales in European ports.

- Shear Beam: Needs rigid mounting base to prevent deflection. Popular in US food processing for tank weighing.

Step 4: Account for Environmental and Regional Factors (GEO Optimization)

Your geographic location dictates specific load cell requirements:

Nordic Region (Sweden, Norway, Finland, Iceland)

Environmental Challenges: -40°C temperatures, ice loading, condensation

Capacity Considerations: Add 10-15% capacity for ice accumulation on outdoor platforms

Certifications Required: CE marking, optional OIML R60 for trade

Material Choice: Stainless steel 17-4PH to prevent corrosion from road salt

Southeast Asia (Thailand, Vietnam, Indonesia, Malaysia)

Environmental Challenges: 90% humidity, monsoon rains, tropical temperatures

Capacity Considerations: Humidity can add moisture weight to hoppers (account for 2-5% extra)

Certifications Required: Metric system (kg) calibration, localPattern Approval

Material Choice: IP68/IP69K stainless steel essential for rice mills and fishing industries

Middle East (UAE, Saudi Arabia, Qatar)

Environmental Challenges: 50°C ambient temperatures, sandstorms, chemical exposure

Capacity Considerations: High-temperature load cells lose 10% capacity at 100°C

Certifications Required: ATEX for oil/gas, UAE-specific Metrology compliance

Material Choice: High-temperature alloy steel, sand-resistant cable glands

North America (USA, Canada)

Environmental Challenges: Wide temperature swings (-30°C to +40°C), NEMA washdown requirements

Capacity Considerations: US uses lb (pounds) vs metric tons—ensure unit consistency

Certifications Required: NTEP (National Type Evaluation Program) for legal trade, Measurement Canada approval

Material Choice: NEMA 4X (IP66 equivalent) for dairy and meat processing

Australia and New Zealand

Environmental Challenges: Extreme UV, dust (Outback), coastal salt spray

Capacity Considerations: Mining trucks require 150-tonne+ capacity cells with 300% overload

Certifications Required: NMI (National Measurement Institute) pattern approval

Material Choice: Heavy-duty nickel-plated alloy steel for mining, 316 stainless for coastal regions

Latin America (Brazil, Argentina, Chile)

Environmental Challenges: Heavy rains, agricultural chemicals, altitude variations

Capacity Considerations: Coffee and grain exports require high-precision 0.01% accuracy

Certifications Required: INMETRO (Brazil), INTA (Argentina)

Material Choice: Chemical-resistant epoxy coatings for fertilizer handling

Step 5: Select Output Signal and Electronics Compatibility

Your load cell output must match your indicator or PLC:

- mV/V Analog: Standard 2mV/V or 3mV/V signal. Requires 4 or 6-wire configuration for long cable runs (common in large European tank farms).

- 4-20mA: Better for noisy industrial environments like Middle Eastern steel plants.

- Digital (RS-485, CANbus): Essential for multi-cell applications (truck scales) to prevent corner errors. Popular in modern US logistics hubs.

Cable length considerations: In Australian mining operations where indicators sit 50+ meters from scales, use 6-wire systems with sense lines to compensate for voltage drop.

Step 6: Verify Legal and Trade Requirements

If used for commercial transactions, your load cell must meet local metrology laws:

- Accuracy Classes: OIML Class C3 (3000 divisions) standard for Europe; NTEP Class III (5000 divisions) for USA

- Verification Interval (e): Must match your required scale division size

- Multiple Cell Systems: All cells must be same capacity and model (mixed capacities illegal for trade in most regions)

Common Selection Mistakes to Avoid

1. Ignoring Side Loads and Eccentric Loading

Installing a load cell without checking for side forces reduces effective capacity by 20-30%. Always use sway bars or stay rods in outdoor applications (common mistake in Southeast Asian silo installations).

2. Wrong Material for the Environment

Using aluminum load cells in coastal Australia or Florida results in galvanic corrosion within 2 years. Always upgrade to stainless steel within 50km of coastlines.

3. Underestimating Shock Loads

Dropping materials onto scales (like in Canadian logging operations) creates impact forces 3-5x the static weight. Use shock-absorbing mounts or select 3x capacity cells.

4. Temperature Compensation Mismatch

Standard load cells compensate for -10°C to +40°C. Nordic winter operations (-30°C) or Middle Eastern summer (60°C surface temperatures) require extended range compensation.

Load Cell Sizing Checklist by Industry

Agriculture and Farming

- Grain silos: 2-5 tonne cells with bird-proof cable entry (North America)

- Livestock scales: 1-2 tonne with anti-corrosion coating (high ammonia environments)

- Feed bins: IP67 minimum for dust protection (Australian outback)

Manufacturing and Process Control

- Mixing tanks: 4-cell configuration with 2:1 safety factor (European chemical plants)

- Conveyor belts: Single-point cells for uniform loading (Asian electronics manufacturing)

- Checkweighers: Aluminum single-point, 50kg capacity, 0.01g precision

Transportation and Logistics

- Truck scales: 30-45 tonne digital cells with lightning protection (US highways)

- Rail scales: 100-tonne compression cells with hermetic sealing

- Axle weighers: Portable 10-tonne cells with ramps (Brazilian agricultural roads)

Pharmaceutical and Food

- Tablet presses: 50kg bending beam, IP65 washdown (FDA compliant for US)

- Tank weighing: 316L stainless steel for CIP/SIP cleaning (EU hygiene standards)

- Packaging: 100-500kg single point with checkweigher certification (Asia-Pacific)

Budget Considerations: Price vs. Performance

Load cell pricing varies by region and specification:

- Standard Alloy Steel: $50-200 USD (Chinese manufacturing, general industrial)

- Stainless Steel IP68: $200-800 USD (European food/pharma, coastal applications)

- High-Temperature Specialty: $1000+ USD (Middle Eastern steel, Nordic LNG facilities)

- Digital/Precision: $500-1500 USD (US legal-for-trade truck scales)

Rule of thumb: Spending 20% more on the correct environmental protection saves 200% in replacement costs over 5 years.

Frequently Asked Questions About Load Cell Selection

What happens if I use a load cell with too much capacity?

Over-capacity load cells provide poor resolution. A 10,000kg cell measuring 100kg loads offers only 1% accuracy at best. Choose a cell where your typical load falls in the 50-80% range of capacity.

How do I calculate load cell capacity for a tank with agitation?

Add 30-50% to the static weight calculation for dynamic forces. For heavy agitation in chemical processing, use a 2x safety factor minimum.

Can I mix different load cell capacities on one platform?

No. All load cells in a multi-cell system must have identical capacity and output sensitivity (mV/V). Mixing causes corner errors and violates trade laws in USA, EU, and Australia.

What is the difference between OIML and NTEP approval?

OIML (Europe/Asia) uses accuracy classes C, D; NTEP (USA) uses Class III, IIIL, IIIM. A load cell approved for one may not legally be used in the other region without recertification.

How does altitude affect load cell selection?

High altitude (Andes, Colorado) reduces air buoyancy effects by 0.1-0.3%, but more critically, affects cable insulation. Use high-altitude rated cables above 3000m elevation.

What size load cell do I need for a floor scale?

For a 1000mm × 1000mm platform: use four 500-1000kg shear beam cells (one per corner). For 2000kg capacity total, each cell handles 500kg static + dynamic factor.

Can I use one load cell rated for total weight instead of four?

Only for center-load applications like hanging scales. Platform scales require multiple cells to prevent corner errors and tipping. Single-cell platforms are limited to 300-400mm diameter.

What IP rating do I need for outdoor use?

Minimum IP65 for covered areas, IP67 for exposed to rain, IP68 for submerged (washdown) or 1m water depth. In tropical climates, IP68 is mandatory even for "dry" applications due to humidity.

Final Checklist Before Purchase

Before ordering, verify:

☐ Capacity = (Max Load + Tare) × 1.5 minimum safety factor

☐ Physical dimensions match mounting hardware

☐ Environmental rating suits your climate zone

☐ Output signal matches indicator/PLC (mV/V, 4-20mA, or digital)

☐ Certification valid for your country (NTEP/OIML/local)

☐ Cable length sufficient for controller distance

☐ Material compatible with chemicals/corrosives present

☐ Temperature compensation range covers local extremes

Conclusion

Choosing the right load cell capacity and size requires balancing mechanical requirements, environmental protection, and regional compliance standards. By following this calculation method—accounting for dynamic loads, safety factors, and local climate conditions—you ensure reliable weighing for 10+ years.

Whether installing a precision balance in a Swiss laboratory, a truck scale in Texas, or a mining weighbridge in Western Australia, the principles remain constant: size for the maximum with safety margin, specify for the environment, and certify for local law. When in doubt, consult with a local metrology expert familiar with your region's specific requirements.

Need help calculating capacity for your specific application? Use our Load Cell Calculator tool or contact regional support for Americas, EMEA, or Asia-Pacific specifications.

HOT keyword: