What is load cell Sensor?

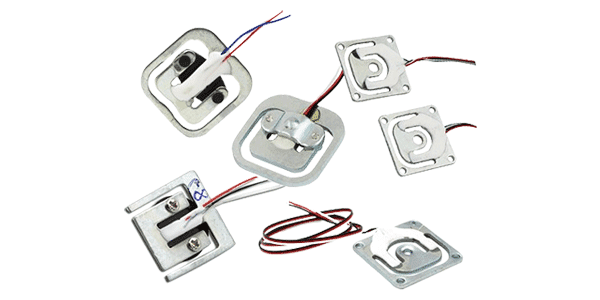

A load cell sensor is a type of transducer that is used to convert force or weight into an electrical signal. It is commonly used in various industries and applications to measure and monitor the amount of force or weight applied to an object or structure. Load cell sensors typically consist of a metal structure with strain gauges attached to it. When a force or weight is applied to the load cell, the strain gauges deform, causing changes in their electrical resistance. These changes in resistance are then converted into an electrical signal that can be measured and analyzed. Load cell sensors are known for their high accuracy, reliability, and ability to withstand heavy loads. They are widely used in industries such as manufacturing, aerospace, automotive, healthcare, and more.

How is a load cell measured?

A load cell is typically measured by the changes in its electrical output, which correspond to the applied force or weight. The measurement process involves the following steps:

Calibration: Before measuring a load cell, it is essential to calibrate it. Calibration involves applying known forces or weights to the load cell and recording the corresponding electrical output. This calibration data is used to establish a relationship between the load cell's electrical output and the applied force or weight.

Installation: The load cell is installed in the system or structure where force or weight measurement is required. It is usually mounted between the object or structure being measured and a fixed point.

Excitation: The load cell requires an excitation voltage to function properly. This voltage is typically supplied by a power source or a signal conditioner connected to the load cell. The excitation voltage energizes the strain gauges attached to the load cell.

Measurement: As force or weight is applied to the load cell, the strain gauges deform, causing changes in their electrical resistance. These changes in resistance result in a corresponding change in the electrical output of the load cell. This electrical output is usually in the form of a voltage or current signal.

Signal Conditioning: The electrical output from the load cell is often weak and requires amplification and filtering to improve its quality and accuracy. Signal conditioning devices, such as amplifiers and filters, are used to process the load cell's electrical output.

Data Acquisition: The conditioned electrical output from the load cell is then acquired using data acquisition systems or instruments. These systems convert the analog signal into digital data that can be stored, analyzed, and displayed on a computer or other devices.

Interpretation: The acquired data is interpreted to determine the force or weight applied to the load cell. This interpretation is based on the calibration data obtained earlier, which establishes the relationship between the load cell's electrical output and the applied force or weight.

Measurement Range: The range within which the load cell sensor can accurately measure the weight. For example, 0-100 kg.load cell bed leveling.

Sensitivity: The smallest weight change that the sensor can detect. It is usually expressed in terms of millivolts per unit weight. For example, 2 mV/kg.

Accuracy: The degree of closeness between the measured weight and the actual weight. It is typically expressed as a percentage of the full-scale range. For example, ±0.1% of full-scale range.

Resolution: The smallest weight increment that the sensor can display or measure. It is usually expressed in terms of the least significant bit (LSB) or the number of decimal places. For example, 0.01 kg.

Linearity: The ability of the sensor to provide measurements that are proportional to the applied weight. It is usually expressed as a percentage of the full-scale range. For example, ±0.2% of full-scale range.

Repeatability: The ability of the sensor to provide consistent measurements for the same weight under the same conditions. It is usually expressed as a percentage of the full-scale range. For example, ±0.05% of full-scale range.

Response Time: The time taken by the sensor to respond to a change in weight. It is usually expressed in milliseconds (ms) or seconds (s). For example, 10 ms.

Operating Temperature Range: The range of temperatures within which the load cell sensor can operate effectively. For example, -10°C to 60°C.

Excitation Voltage: The voltage required to power the load cell sensor. It is usually expressed in volts (V). For example, 5 VDC.

Output Signal: The type of electrical signal produced by the load cell sensor. It can be analog (e.g., voltage or current) or digital (e.g., serial communication protocols like RS-232 or USB).

Overload Capacity: The maximum weight that the sensor can withstand without causing damage. It is usually expressed as a percentage of the full-scale range. For example, 150% of full-scale range.

Environmental Protection: The level of protection provided by the sensor against dust, moisture, and other environmental factors. It is usually indicated by an IP (Ingress Protection) rating. For example, IP65.